The operation of the producing line is highly emphasized since the sandstone aggregate is the base of the architect materials. Base on the medium and long term development plans for national infrastructure, sandstone consumption is expected to increase by more than 10% every year, and the sand made from cobblestone accounts for 60%. The mining of sandstone is gradually developing towards the scale, yield, and environment protection, and in addition, the government limits natural sandstone mining in recent years, the exploitation of machine-made sand is more and more important.

The sandstone industry in China has developed in a rough and tradition way for a long time period. With the increasing protection of the natural sandstone and the environment, the green development concept of low energy consumption, low emission and low pollution is gradually promoted. The sandstone aggregate industry, as an industry with high pollution and high energy consumption, is facing unprecedented challenges.

| The advantages of CHAENG new-type sandstone aggregate production line | Problems faced by traditional sandstone aggregate production line |

|---|---|

| Reasonable grade of finished product, and high quality Product Quality | Rough finished grain shape, and uniform quality |

| Wet process, being environmental friendly Process | Dry process, resulting in serious dust pollution |

| Advanced equipment with low operating costs, intelligent control to save the cost.Re-treatment of wastewater and sludge, to increase second profit Cost and Benefit | Low access standard and low utilization rate of ore resources; Large overall energy consumption, and high cost |

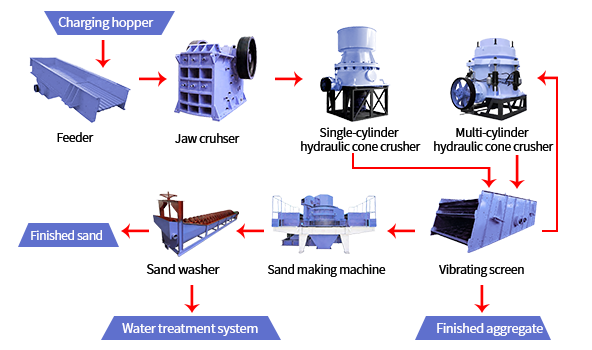

After the ore raw material is coarsely crushed, it is fed into a jaw crusher for primary crushing and screening, and then through the conveyor sequentially enters medium crushing and fine crushing cone crushers. At the meantime, the material of 5-30mm is separated by the screening system and stored in the buffer bin at the top of the sand making machine, and then is sent into four vertical shaft crushers via the feeder. Afterwards it is conveyed by a belt conveyor to the finished screening shop. The material of >20mm is returned to the sand making machine through the belt conveyor for crushing; the material of 10~20mm is stored as the finished product in the finished product shed; the material of 0~5mm enters the washing system through the chute.

In the whole production line, the crushing system is divided into three parts: primary crushing, medium & fine crushing and sand-making crushing.

Primary crushing: 140mm < material fineness≤800mm

Medium & fine crushing: 30mm<material fineness

sand-making crushing: 5~30mm

After the sludge-containing wastewater is dewatered by the cyclone and the dewatering screen, the slurry flows into the lifting tank and is transported by the lift pump to the horizontal sedimentation tank. The bottom flow is sent to the sludge tank through the plunger pump, and the upper clear liquid flows into the clear water tank for production use. The slurry in sludge tank is sent to the filter press by the filter press feed pump. After the pressure filtration, the mud cake is transported by the belt conveyor to the yard of the plant, and the filtered water is discharged into the clear water tank for recycling.

After the crushing of each part, the material will enter the corresponding material fineness screening system, and is distributed to the corresponding crushing system according to the fineness.

Fully enclosed finished product shed without dust leakage can meet the storage requirements of natural sandstone, machine-made sand and finished aggregate.

The material of 0-5mm separated by the screening systems is firstly cleaned by their respective sand washing systems, then dewatered by the dewatering screen, and finally stored in the finished product shed.

Intelligently controlling the entire process of vehicle from weighing to loading and delivery can simplify the process and integrate the corresponding information system and automatic system, so as to reduce manual operations and comprehensively improve delivery efficiency and customer satisfaction.

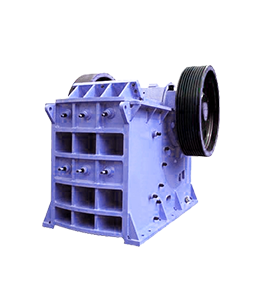

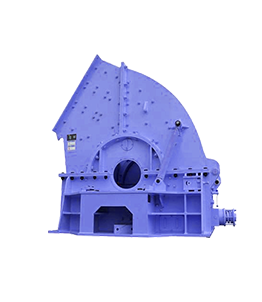

Traditional jaw crusher is an ideal alternative upgrade product

Advantages:

1.Deep cavity crushing, being efficient and energy saving

2.Advanced technology, lower failure rate and long service life

3.Large adjustment range of outlet size and multiple functions

4.With low noise and little dust, meeting environmental protection requirements

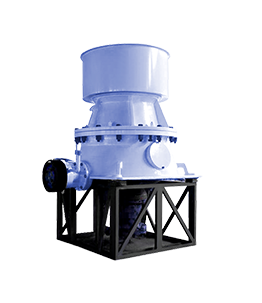

Divided into single cylinder and multi cylinder, suitable for medium crushing and fine crushing.

Advantages:

1.The grain shape is neat and the output is high.

2.Strong crushing capacity.

3.Upgraded structure, high production efficiency.

4.Low consumption of consumable parts and low running cost.

Suitable to crush the brittle material of medium hardness in many industries

Advantages:

1.Large crushing ratio and large feeding amount.

2.Low operating cost and low production cost.

3.Long service life and low maintenance cost.

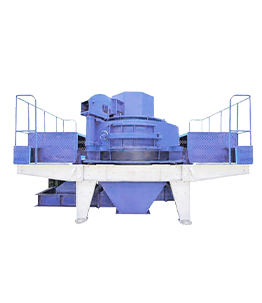

CHAENG sand making machine is a necessary equipment for artificial sand making and stone shaping.

Advantages:

1.The "stone impacts stone" working mode reduces customer’s production costs.

2.The new automatic protection device provides high safety.

3.The lower part of the machine body effectively prevents the blockage by the materials with high water content.

GPEV Series Jaw Crusher

| Model | Inlet port width | Inlet port length | Feed size | Minimum outlet port | Maximum outlet port | Installed power | Min. capacity | Max. capacity | Outline L | Outline W | Outline H |

| GPEV500×750 | 500mm | 750mm | 425mm | 50mm | 100mm | 55Kw | 40T/h | 100T/h | 2053mm | 1921mm | 2000mm |

| GPEV580×930 | 580mm | 930mm | 460mm | 60mm | 175mm | 90Kw | 120T/h | 455T/h | 2880mm | 1755mm | 1460mm |

| GPEV700×1060 | 700mm | 1060mm | 560mm | 70mm | 200mm | 110Kw | 155T/h | 580T/h | 3320mm | 2030mm | 2005mm |

| GPEV750×1060 | 750mm | 1060mm | 630mm | 80mm | 140mm | 90Kw | 110T/h | 320T/h | 2655mm | 2302mm | 3110mm |

| GPEV760×1100 | 760mm | 1100mm | 640mm | 75mm | 200mm | 110Kw | 150T/h | 350T/h | 2600mm | 2500mm | 2200mm |

GCP Series Cone Crusher

| Model | Discharge size | Installed Power | Min. capacity | Max. capacity | Chamber | Auxiliary classification |

| GCPF500 | 32mm | 400Kw | 400T/h | 530T/h | C2 thick | HP Hydraulic |

| GCPF300 | 16mm | 220Kw | 170T/h | 215T/h | M middle | HP Hydraulic |

| GCPF500 | 38mm | 400Kw | 425T/h | 580T/h | C1 Super thick | HP Hydraulic |

| GCPF300 | 22mm | 220Kw | 220T/h | 260T/h | C2 thick | HP Hydraulic |

| GCPC440 | 25-51mm | 220Kw | 195T/h | 486T/h | S2 middle thick | Single Cylinder Hydraulic |

| GCPC440 | 29-51mm | 220Kw | 225T/h | 511T/h | S2 middle thick | Single Cylinder Hydraulic |

| GCPC440 | 35-54mm | 220Kw | 267T/h | 601T/h | S1 Super thick | Single Cylinder Hydraulic |

| GCPC660 | 38mm | 315Kw | 318T/h | 895T/h | S2 middle thick | Single Cylinder Hydraulic |

| GCPC660 | 41mm | 315Kw | 345T/h | 1050T/h | S1 Super thick | Single Cylinder Hydraulic |

Based on the waste stone which is generated by building the ten thousand acres artificial lake in Huixian, and combined with the river sand mining remediation, the sandstone production base comes into being. The production line is constructed by CHAENG. The production line process is simple and smooth, and the whole production line is environmental protected.

Raw material: river pebbles

Output: 5 million tons per year

Equipment selection:

jaw crusher + two-stage cone crusher+vertical shaft crusher + three-stage circular vibrating screen

Finished products:

natural sand, mechanical sand, and 10-20mm aggregate.

Technological advantage:

"three sections and a closed circuit", a wet production process

Adopt advanced and reliable DCS control system, and one-card-controlled loading system, which has high level of automation to reduce production cost.

The overall layout of the plant is designed in strict accordance with the modern, professional and garden-style sandstone production plant.

Strictly control noise and dust, adopt fully enclosed steel structure workshop, reduce the noise for environmental protection, and the dust index in the workshop is better than national standard (≤10mg/m3)

Deeply cultivated in building materials and equipment for more than 60 years, we know these better

60 years’ experience in producing cement building materials and equipment

Cooperation with more than 1000 cement factories and commercial enterprises

Screening the aggregates layer by layer according its level

Better understanding the customer’s requirement

CHAENG’S Strength

CHAENG’S Strength

CHAENG’S Strength

CHAENG’S StrengthWith large casting base, machining and assembling workshop, CHAENG has strong casting and processing strength. All the main engines for the turnkey project are self-made, and other supporting auxiliary machines are bought from excellent brands at home and abroad, which means that we can control the whole quality and construction period of the project.

Assembling workshop + machining workshop + casting base, Refer to the sample book

The company has a professional technical team in many fields with more than 100 people, such as technology, equipment, hydraulic, electrical and civil engineering. So we can design the whole sandstone aggregate production line independently.

We stick to independent research and innovation all the time, continuously optimize product performance and improve the technological content of products.

We have research center of aggregate, powder and high-performance concrete, so we can provide scientific and professional sandstone aggregate production system solutions for the customers.

CHAENG has won man honorary awards, such as “top 100 suppliers in China cement industry”, “top 10 innovative enterprise in China cement industry”, “high-growth private enterprise in Henan Province”, “technological innovation demonstration enterprise of energy conservation and emission reduction in Henan Province”, “National high-tech enterprise” and so on.

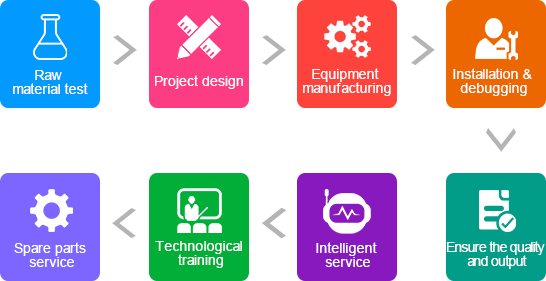

CHAENG Services

CHAENG ServicesWe have a professional design, manufacturing, installation and debugging team, which can provide customers with material performance analysis, equipment and spare parts are completely produced by CHAENG, so we can provide customers with one-stop integrated service.