According to relevant data,it shows that the general trend of cement industry is with strength of cement rising and the clinker consumption decreasing in the Germany and Switzerland of the power cement world.In the future development of cement industry in Germany, it is still that the traditional Portland cement will be replaced by cement which is mixed with low clinker such like slag, fly ash, shale, ash, II sintering limestone, etc. And the slag will be used by more and more cement and concrete enterprises as a new type of admixture. Therefore, slag powder processing can be a global environmental protection and energy saving industry.

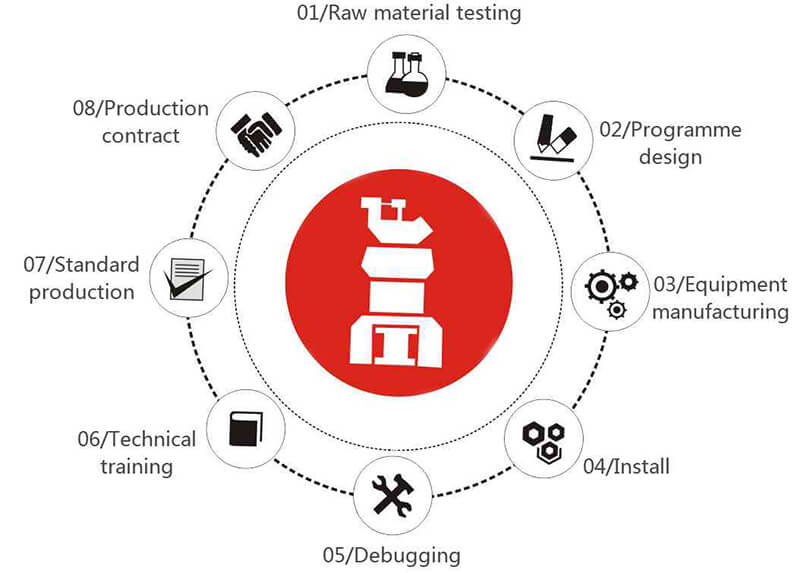

The world's first strategy of "1 vertical mill, 8 services" - let you have no worries all the way

Henan MengDian Group-The famous Chinese cement group, in order to adapt to global environmental protection requirements, they invested to build a slag powder production line with capacity of 1 million tons per year in 2012. This project is overall contracted by us and the production starts smoothly in 6 months. The data shows that our vertical mill’s energy saving effect is remarkable when compared with the ball mill (saving 30%-60%)

| Product Specification | GRMS53.41 Slag Vertical Mill |

|---|---|

| annual output (t) | 1 million |

| designed output (t/h) | 150 |

| designed input (t/h) | 188 |

| actual output (t/h) | 160 |

| product fitness (m2/KG) | 500 |

| single machine power consumption (KWh) | 26.5 |

| The system power consumption (KWh) | 35 |

| coal consumption (KG) | 17 |

| Mineral powder metal recovery (%) | 0.2-0.3 |

Dry slag and wet slag should be put into the mill separately, it can avoid slag agglomerate and decreasing the transmission capacity.

Dry slag and wet slag should be put into the mill separately, it can avoid slag agglomerate and decreasing the transmission capacity.

External loop system uses embedded scraping machine + elevator + pipe hoist iron remover to reduce dust emissions.

External loop system uses embedded scraping machine + elevator + pipe hoist iron remover to reduce dust emissions.

Set the flow warehouse (middle warehouse) steady before sending the slag into the vertical mill to improve the stability of vertical mill.

Set the flow warehouse (middle warehouse) steady before sending the slag into the vertical mill to improve the stability of vertical mill.

Set dust collector on the chute transportation corridor to improve environmental cleaning rate.

Set dust collector on the chute transportation corridor to improve environmental cleaning rate.

Add iron elector to achieve iron slag separation and reduce attrition.

Add iron elector to achieve iron slag separation and reduce attrition.

Crush big bite of slags again to improve the material utilization rate.

Crush big bite of slags again to improve the material utilization rate.

| Country | Company | Project |

|---|---|---|

| Indonesia | Indonesia Growth Steel Group | 300,000 t/a nickel slag grinding production line |

| China | Baosteel Group Corporation | 1,500,000 t/a slag/steel slag grinding production line |

| China | Aosen Steel Co.,Ltd | 600,000 t/a slag grinding production line |

| China | Xuzhou South-East Steel Co.,Ltd | 300,000 t/a slag grinding production line |