Besides tailings, the solid waste discharged from iron and steel enterprises is mostly smelting slag, mainly including blast furnace slag, slag, steel slag, iron alloy slag, etc. The smelting slag storage not only occupies a large amount of land, but also causes certain environmental pollution, and causes harm to the health of the public. Therefore, the comprehensive utilization of steel slag to achieve its reduction, reuse and harmlessness is very necessary for the sustainable development of the steel industry.

Until this article is published, the 300,000t/y GGBS Plant uses GRMS33.31 vertical roller mill as the host machine, with the design yield of 45t/h, the actual output of 50t/h, and the specific surface area of 4200cm2/g. The heat of hot air furnace is 8,000,000kcal/h, and the water content of the finished product is less than 1%. The equipment operates well and every indicator is normal, fully meeting the production requirements of the customers. It is reported that the 300,000t/y GGBS Plant project in Indonesian built by CHAENG cooperating with POSCO is under construction and expected to be put into production in July. Please follow up on the official website later.

The finished slag micro-powder will be used as ceramsite to improve soil, so as to increase the yield and quality of crops, and also will be sold as the cement additive.

Piles of slag are taken and fed by the forklift truck, and conveyed by a belt conveyor. During the process of conveying, slag raw material will be iron-removing and screening through magnetic separator and vibrating screen, and then go to the weigher cabin, elevator and last to the vertical roller mill for grinding process. The ground granulated slag powder is drying by the hot air supplied by hot blast furnace, and with the help of hot air, the powder selecting is made in the separator. The qualified slag powder particles will be collected by bag dust collector, then conveyed to and stored in the silos by the air slide and elevator.

The host machine in this project is GRMS33.31 vertical roller mill with an annual output of 300,000 tons. Vertical roller mill produced by CHAENG can meet the GGBS Plant of 200,000 tons to 1.5 million tons per year. CHAENG currently has more than 100 customers, 80% of which are GGBS Plants with annual capacity of 1 million tons, 600,000 tons, and 300,000 tons. The parameters of these three models in terms of equipment selection and energy consumption are displayed for reference:

| Specification | GRMS53.41 Vertical roller mill | GRMS46.41 Vertical roller mill | GRMS33.31 Vertical roller mill |

|---|---|---|---|

| Annual capacity (t) | 1,000,000 | 600,000 | 300,000 |

| Designed capacity (t/h) | 150 | 90 | 45 |

| Feeding capacity (t/h) | 188 | 125 | 65 |

| Actual capacity (t/h) | 160 | 105 | 55 |

| Finished product fineness (cm²/g) | 500 | 500 | 500 |

| Power consumption/unit (KWh/t) | 26.5 | 28.5 | 30 |

| System power consumption (KWh/t) | 35 | 37 | 42 |

| Coal consumption (equivalent to standard coal) (kg) | 17 | 18 | 18 |

| Metal recovery rate per ton of slag powder (%) | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

POSCO selected the CHAENG GRMS33.31 vertical roller mill. The process is designed as “One vertical roller mill, two purposes” for the customer's demands, with two feed openings. Different materials can use different feed openings, and the different material conversion takes only 40 minutes, thus one production line can grind two kinds of materials.

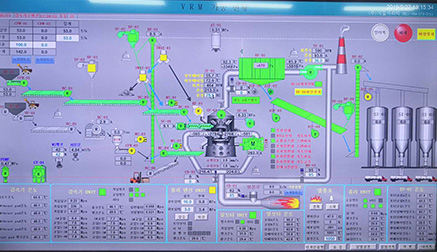

GGBS plant system adopts DCS central control system, all operation parameters can be adjusted in the middle control, the system response is fast, and the operation is simple and easy.

CHAENG has a large steel casting base with all the mainframe and spare parts self-supporting. We can guarantee the delivery process, and provide fast and high quality service for our cunstomers in customizing spare parts.

1.5 million t/y EPC Steel slag and GGBS Compound powder production line for Shanghai Baosteel

300,000t/y nickel slag grinding plant for PT. Indoferro

“one mill, three purposes” EPC project in Henan: the production line annually outputting 600,000 tons of ggbs / 900,000 tons of cement / 1 million tons of auxiliary materials

300,000t/y EPC steel slag grinding plant for Xuzhou Southeast Steel

CHAENG was found in 1958, located in National Sustainable Development Experiment Area,Mengzhuang Town, Huixian City, Henan Province.Since we produced the first ball mill in 1968, our factory has produced more than 3000 sets mills and rotary kilns.Along with the national “The Belt and Road” strategy, and actively go out, our products are exported to the US, Germany, Russia, Japan, Korea, Indonesia, Uzbekistan, Pakistan, Vietnam and more than 60 countries and regions, and has achieved long-term cooperation with Sinoma, Shanghai Baosteel, Korea POSCO and other well-known enterprises at home and abroad, and becomes industrial waste slag resource recycling national high-tech enterprises. CHENG has achieved gorgeous turn from a single equipment supplier to the grinding system integrated service provider of friendly environment builders.