Chaeng upgraded version of lime rotary kiln for customers favored

Recently, Chaeng(Great Wall Machinery Co., Ltd.) and Guangxi Hua Yan ore source Ltd. signed a purchase contract φ4.0 × 60m rotary kiln, the device is mainly used in the nano calcium carbonate production line, production line supporting the coal mill bag filter and also by Chaeng supply. National Day is approaching, Chaeng has signed a large single machine, which makes the Great Wall machinery National icing on the cake.

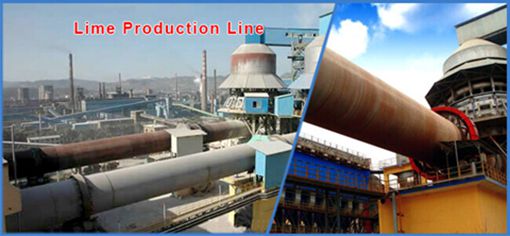

Chaeng lime kiln is another masterpiece, an upgraded version of lime more customers favor. Lime kiln lime kiln referred to, also known as active lime kiln, widely used in cement, chemicals, non-ferrous metallurgy, ferrous metallurgy, refractory materials, ceramics and paper, and other fields. As a professional manufacturer of lime, the Chaeng currently available for the production of Nissan 1200 tons or less lime kiln equipment, and from the design, manufacture, installation, commissioning one-stop "turnkey" service, ensure that customers can in a very short achieve production within a period of time.

As the leading manufacturer of lime, Chaeng in constant development, using the latest technology to create cost-effective kiln equipment, to achieve a win-win with customers. Chaeng upgraded kiln advanced production technology, production.

Its main advantages:

A higher: because the material in the kiln even rolling forward, heat evenly, stable product quality, raw, burnt a lower rate can be calcined lime with high activity, the activity of lime under the same conditions, lime production shaft kiln higher than the average high 30ml, activity of up to 400ml, or even higher.

Second, the greater: High yield lime, Chaeng has built many Nissan 150 tons -1200 tons of active lime kiln production lines, running in good condition, suitable for medium and small enterprises to use lime.

Third, more environmentally friendly: Chaeng calcining kiln belonging to the open, high-tech production process, kiln structure is simple, airflow, the gas can be discharged in the sulfur smoke, fuel sulfur easy attachment, and thus lower product sulfur content desulfurization efficiency up to 85%.