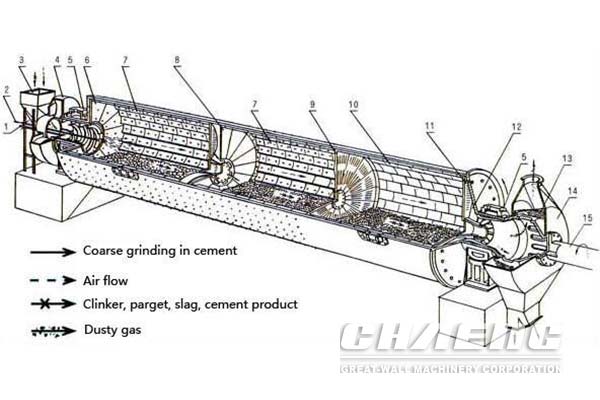

Three-cabin cement ball mill is a common ball mill. The internal barrel is divided into three parts in order to achieve higher fineness of grinding requirement. φ4.2*13m three-cabin cement mill produced by Great Wall Machinery has the advantage of low power consumption and high grinding efficiency, so it is the ideal equipment for clinker grinding.

1. Three-cabin cement ball mill

The production line adopts the mature three-cabin clinker ball mill manufactured by Great Wall Machinery. The equipment adopts advanced process, the grinding control to clinker reaching a high level. Compared with traditional clinker ball mill, the product quality is improved significantly.

2. Rotary kiln

The equipment adopts advanced hydraulic gear wheel device, and adopts metering plunger pump with high measuring accuracy, high-precision flow speed control valve, contact graphite block sealing device and other domestic advanced technologies. It is easy to operate and its performance is reliable. Compared with equipment with the same specifications, the operation rate increases by 10%, yield by 5%-10%, heat rate reduces by 15%.

3. Adopting computer distributed control

Realizing the automation of cement production process, high efficiency, excellent quality, low energy consumption and environmental protection.

Since the cement production line went into operation, the production capacity of Huaxin Power Group Co., LTD improves significantly. The cement production line adopts the latest and the most advanced dry process production technology, reducing the consumption of raw material on the whole and improving the output.

With the output increasing, the initial costs have been recovered. Meanwhile, as the sales range expands constantly and the impact improves gradually, Huaxin Power Group Co., LTD steps into the forefront of cement industry

Founded in 1958 and located in Xinxiang, Henan province, CHAENG has 60-year experience in equipment manufacturing with an area of 330,000 m2 and 1 billion RMB of annual production value. The company is specialized in manufacturing all kinds of ball mills, rotary kilns, vertical mills, large steel castings. And we can undertake the EPC projects of cement production line, quick lime production line, blast furnace slag/ steel slag/ nickel slag grinding plants. Its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT, etc.