Capacity: 30-250 t/h

Power: 25-30 KWh/t

Specific surface area: 330-380m²/Kg

Brand: CHAENG

Application: Clinker grinding in cement plants and grinding stations

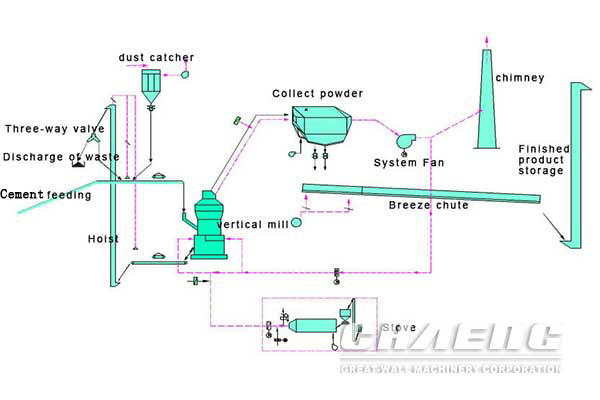

The GRMK cement vertical roller mill of CHAENG adopts a new generation of cement grinding technology, which integrates grinding, drying and powder selecting functions. It can save 30% of power per ton compared with traditional ball mill. At the same time, it has many advantages, such as less auxiliary equipment, multiple functions, small occupied area and little dust pollution. It is widely used for clinker grinding in cement plant.

The biggest advantage of CHAENG is to have a large casting base and large machining workshops, which greatly shortens the delivery cycle of cement vertical mill.

GRMK vrm cement mill has the advantages of compact structure and small volume. It mainly includes high efficiency separator, grinding rollers, grinding table, hydraulic loading device of grinding roller, hydraulic lubrication system, reducer, motor, and electrical components.

1. Separator is an efficient and energy-saving powder selection device.

2. Grinding roller is used to grind and crush materials.

3. The grinding table is fixed on the output shaft of the reducer. It is the place where the grinding rollers grind materials.

4. The hydraulic loading device is a component that provides grinding pressure for the roller. And it provides sufficient pressure to crush the materials.

CHAENG has the domestic first-class technical team and rich production experience, and its cement vertical mill has the following advantages:

1. CHAENG vertical mill comprehensive power consumption is 25kwh/t, saving more than 30% of power compared to the traditional ball mill system.

2. According to the market demand, it is convenient to adjust the cement varieties.

3. High cement quality to meet the construction requirements

4. Good material adaptability: more adaptable to the materials which has high water content and are hard to be crushed and worn.

5. Simple process, small occupied area, a small number of mechanical and electrical equipment, easy operation and maintenance.

6. Integrate functions of grinding, drying and powder selecting, with small noise and little wear.

CHAENG can provide a variety of schemes for cement grinding, and make a choice according to the actual situation and needs of customers:

| Program recommended | Closed-circuit ball mill system | Combined grinding system | Vertical final grinding mill system | |

|---|---|---|---|---|

| Cement types | P·O42.5 | P·O42.5 | P·O42.5 | |

| Cement proportioning ratio(%) | Clinker | 90 | 90 | 90 |

| Limestone | 5 | 5 | 5 | |

| Gypsum | 5 | 5 | 5 | |

| Cement specific surface area (cm²/g) | 3500 | 3500 | 3500 | |

| Capacity (t/h) | 170 | 160 | 160 | |

| System power consumption (KWh/t) | 41 | 33 | 28 | |

| Annual electricity savings (×10,000 Yuan) | — | 400 | 700 | |

| Metal wear (g/t) | 50 (Steel ball) | 30 (Steel ball+Roller surface) | 5 (grinding roller+grinding table) | |

| Dry capacity | Weak | medium | Strong | |

| Specifications | Grinding Table Diameter (mm) | Output (t/h) | Motor (kW) | Output (t/Y) |

|---|---|---|---|---|

| GRMK26 | 2600 | 40~45 | 1250 | 250,000 |

| GRMK30 | 3000 | 50~55 | 1400 | 300,000 |

| GRMK33 | 3300 | 60~65 | 1600 | 400,000 |

| GRMK36 | 3600 | 75~85 | 2000 | 500,000 |

| GRMK38 | 3800 | 85~95 | 2240 | 550,000 |

| GRMK40 | 4000 | 100~110 | 2500 | 600,000 |

| GRMK43 | 4300 | 125~135 | 3150 | 800,000 |

| GRMK46 | 4600 | 140~160 | 3550 | 900,000 |

| GRMK50 | 5000 | 160~180 | 4000 | 1,000,000 |

| GRMK53 | 5300 | 180~200 | 4500 | 1,200,000 |

| GRMK56 | 5600 | 210~220 | 5300 | 1,300,000 |

| GRMK60 | 6000 | 250~270 | 6300 | 1,500,000 |

| GRMK65 | 6500 | 300~330 | 7300 | 1,800,000 |

| GRMK70 | 7000 | 350~380 | 8500 | 2,200,000 |

Remarks: vertical mill type spectrum benchmark:

(1) Medium Friction MFk=0.9-1.0;

(2) Cement Blaine Test: 3300-3800cm²/g, the bigger of the Blaine test, output will decrease accordingly;

(3) Final cement moisture 0.5-1.0%;

(4) The specific installed power and technical parameters can be adjusted appropriately according to the actual material property and owner's requirement.

1. 300,000 t/a Vertical Cement Mill in Pakistan

2.GRMK3331 Cement Vertical Mill in Uzbekistan