Capacity: 15-260 t/h

Diameter of grinding table: 2600-5600 mm

Specific surface area: 420-450 m²/kg

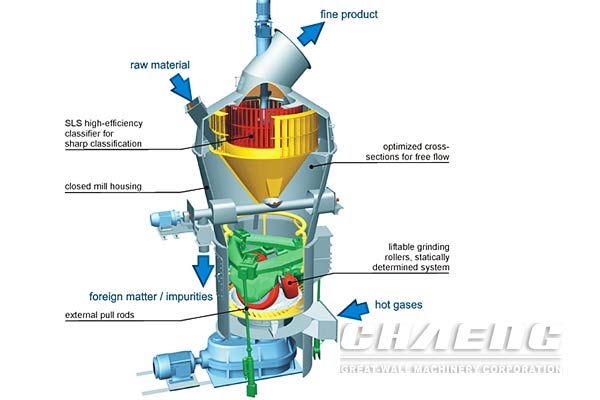

The material through the feed tube fell into the center of the slag vertical roller mill and then the materials outwards the surrounding area of grinding table at centrifugal force, to form a certain thick layer of materials bed, at the same time, the material was crushed by the vertical mill grinding rollers.

The slag materials continuous moving to the outer edge of the grinding table, when the material leaving the grinding table and encounters the hot gas entering the mill through the air ring and it will rise into the middle of the separator, in this course materials and hot gas got a fully heat exchange, the water quickly evaporates.

Separator controls the finished product output size, particles larger than the specified size are separated and fall back to the grinding table, and the materials that meet the fineness requirements enter the finished product warehouse through the powder separator.

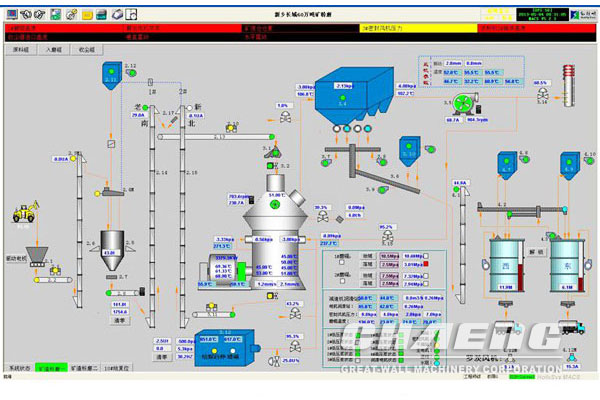

1. Reduce investment costs, intelligent control

GRMS integrates the functions of crushing, grinding, drying, separating and conveying, with compact structure, covering an area of approximately 50% of that of ball mill system. And it can be laid outdoors, so that investment cost is greatly reduced; it is equipped with PLC/DCS automatic control system, can realize remote control and simple operation.

2. Adjust fineness according to demands

A new efficient cage-shaped rotor separator ensures the finished surface area can be adjusted flexibly in the range of 400~550 ㎡/kg, to meet customer different requirements on fineness.

3. Power consumption per set of GRMS is not more than 30Kwh

The horizontal grinding table and conical grinding roller are adopted to ensure the material to form a stable material bed. The energy consumption is low, saving 30% - 40% compared with the ball milling system;

| Specifications | GRMS53.41 slag vertical roller mill | GRMS46.41 slag vertical roller mill | GRMS33.31 slag vertical roller mill |

|---|---|---|---|

| Designed output | 150 | 90 | 45 |

| Actual output | 160 | 105 | 55 |

| Finished fineness (㎡/Kg) | 430 | 430 | 430 |

| Power consumption (KWh/t) | 26.5 | 28.5 | 30 |

| System power consumption (KWh/t) | 35 | 37 | 42 |

| Metal recovery rate of per-ton slag (%) | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

4. Remarkable energy-saving and environmental protection, convenient maintenance

The system is in the state of negative pressure, no dust overflow. Environment is clean, meeting the environmental protection requirements; through the maintenance of the oil cylinder, turning the rocker arm to replace the roller sleeve and lining plate is convenient and fast, so as to reduce downtime losses.

5. Original spare parts to reduce maintenance worries

Grinding rollers, rocker arms and other spare parts in the whole system are manufactured by CHAENG originally, ensuring the quality and greatly reducing the customer's worries of no where to find the spare parts.

6. Metal recovery rate of per-ton slag is great

Special design of the iron removal device can make pig iron recovery rate reach 0.2-0.3%, so that the per-ton production of slag can get higher metal income, and to avoid the metal "enrichment" phenomenon, reduce the consumption of wearing parts and decrease maintenance costs.

Invest:

Referring to the investment income of GRMS46.41 made by CHAENG, it is can be known that annual benefits can reach 18,000,000 yuan.

| CHAENG self-built annual output of 600,000 tons of slag powder production line investment return (put into operation in April 2011) | ||

|---|---|---|

| Investment calculation | total investment | 50 million |

| Cost calculation | raw material cost | 70 yuan / ton |

| Production costs (wages, electricity, coal, maintenance costs, etc.) | 50 yuan / ton | |

| Profit calculation | per Ton of profits ×annual output | 40 × 60 million = 24 million |

| Economic benefits | 2 years to recover all the investment (currently in full profit status) | |

| Mineral quality | Specific surface area | 500 ㎡ / kg |

| 7d activity index | Can reach about 100% | |

| Activity index | GB above S95 level | |

CHAENG slag(slag product applications) vertical roller mill is applied to the construction of GGBFS production line, such as Indonesia with 300,000 tons/year nickel slag powder production line. By now, CHAENG has built more than 90 slag vertical rollers mill production line at home and abroad.

Picture: 600,000 tons/year slag production line in Hebei Province, China

Picture: GRMS46.41 slag vertical roller mill used in 600,000 tons/year slag production line in Guangdong Province, China

Picture: 600,000 tons/year slag production /1,000,000 tons/year cement production line in Henan Province, China

Picture: GRMS slag vertical roller mill used in 300,000 tons/year GGBFS production line EPC project

| Model | Grinding Table Diameter (mm) | Motor (kW) | Output (t/h) |

|---|---|---|---|

| GRMS19 | 1900 | 560 | 15 |

| GRMS23 | 2300 | 710 | 20 |

| GRMS26 | 2600 | 1000 | 28 |

| GRMS30 | 3000 | 1400 | 40 |

| GRMS33 | 3300 | 1600 | 45 |

| GRMS36 | 3600 | 2000 | 60 |

| GRMS38 | 3800 | 2240 | 65 |

| GRMS40 | 4000 | 2500 | 75 |

| GRMS43 | 4300 | 3000 | 90 |

| GRMS46 | 4600 | 3150 | 95 |

| GRMS50 | 5000 | 4000 | 125 |

| GRMS53 | 5300 | 4500 | 145 |

| GRMS56 | 5600 | 5000 | 155 |

| GRMS60 | 6000 | 6300 | 180 |

| GRMS65 | 6500 | 7300 | 220 |

| GRMS70 | 7000 | 8500 | 260 |

Note: mill spectral pattern benchmark

(1) Material medium friction (MFs)=0.9~1.0;

(2) Material moisture max 15%;

(3) Refined powder granularity 4200~4500 cm²/g;

(4) Refined powder moisture 0.5~1.0%;

(5) The concrete mill installed power and technology parameter will be adjusted appropritely basing on the actual material property and requirements of owner;