Disposing Air Volume: 6900m³/h-450000m³/h

Application: Metallurgy, Electric industry, Chemical industry, Building materials and so on.

As the first-class grinding system supplier in China, CHAENG can provide all the equipment required for the cement production line, slag grinding plant, etc. And dust collector, as the most important link for the collection of the finished products in the whole production line, has become the focus of more and more people.

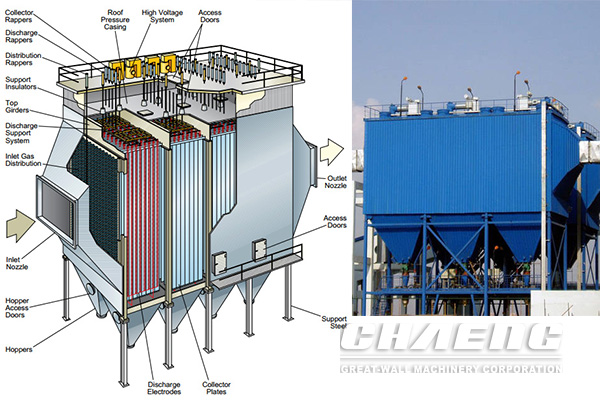

Dust collector of Great Wall machinery includes bag filter, pulse bag filter, electric filter, wet filter, electric bag filter, etc.

There are two main functions: one is to remove dust from the air, protect the environment and reduce pollution. So it is also called the dust removal equipment, such as the dust collecting equipment used in the exhaust emission of the factory.

Another is to collect powder products by collecting dust equipment, such as the cement system to collect the finished cement.

| Parameter of bag filter with pulse plenum | ||||||

|---|---|---|---|---|---|---|

| CCX32-3 | CCX32-4 | CCX32-5 | CCLF2X10 | CCLF4X11 | CCLF4X12 | |

| Disposing air volume | 6900 m³/h | 8900 m³/h | 11160 m³/h | 200000 m³/h | 450000 m³/h | 450000 m³/h |

| Filter area | 96 m² | 128 m² | 160 m² | 3419 m² | 7518 m² | 8170 m² |

| Filtration velocity | 1.19 m/min | 1.15 m/min | 1.16 m/min | 0.94 m/min | 0.95 m/min | 0.92 m/min |

| Quantity of filter bag | 96 | 128 | 160 | 2560 | 5632 | 6144 |

| Equipment resistance | <1700 pa | <1700 pa | <1700 pa | 1500-1800 pa | 1500-1800 pa | 1500-1800 pa |

| Vacuum | ≤6000 pa | ≤6000 pa | ≤6000 pa | 7000 pa | 7000 pa | 7000 pa |

| Inlet concentration | < 200 g/m³ | < 200 g/m³ | < 200 g/m³ | < 400 g/m³ | ≤ 500 g/m³ | ≤ 500 g/m³ |

| Output concentration | ≤ 20 mg/Nm³ | ≤ 20 mg/Nm³ | ≤ 20 mg/Nm³ | ≤ 20 mg/Nm³ | ≤ 20 mg/Nm³ | ≤ 20 mg/Nm³ |

| Pressure of compressed air | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa | 0.5-0.7 MPa |

| Gas consumption | 0.27 m³/min | 0.37 m³/min | 0.46 m³/min | 6 m³/min | 13 m³/min | 14.5 m³/min |

| Length of filter bag | 2450 mm | 2450 mm | 2450 mm | 3200 mm | 3200mm | 3200mm |

1. PLC microcomputer program controller, highly automatic

The pulsed bag filter adopts PLC microcomputer program controller, which includes constant pressure (automatic), timing (automatic), manual.

2. Few secondary dust-emission

Separate chamber for cleaning ash to avoid the secondary dust-emission after blowing clean ash.