Capacity: 200,000-1,500,000t/a

Specific surface area: 450~500 m²/kg

System power consumption: ≤50 kWh/t

The GRMSS steel slag vertical mill of CHAENG is a kind of special equipment for grinding industrial waste such as steel slag and water slag into powder. Integrating crushing, transporting, grinding and drying, the steel slag vertical mill is a kind of ideal equipment for grinding steel slag. The models of CHAENG’s GRMS steel slag vertical mill are complete, including GRMSS33.31、 GRMSS46.41、 GRMSS53.41 and so on, which can meet the needs of the steel slag production line project with an annual output of 200,000-1,500,000 tons.

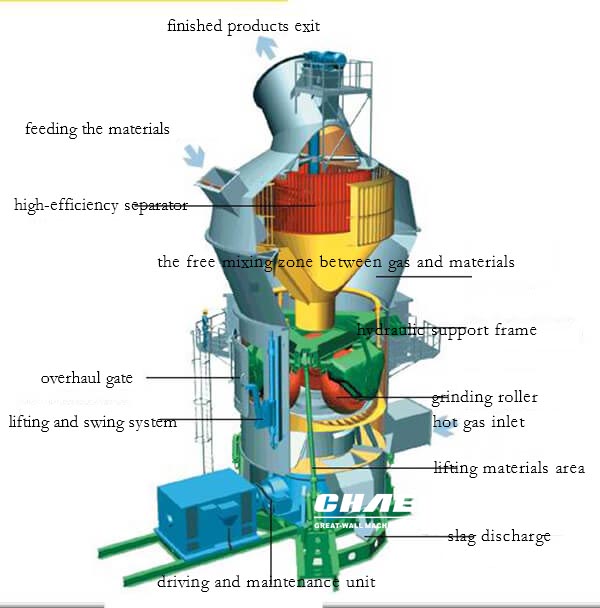

The materials fall to the center of the grinding table through the blanking pipe, then the grinding table is rotating at the constant speed and disperses and spreads out the materials evenly with the aid of centrifugal force, which makes the grinding table become the material bed with a certain thickness. Then several grinding rollers on the grinding table grind and crush the materials at the same time. With the continuous centrifugal force, the materials constantly move toward the outer edge of the grinding table. When the materials that leave the grinding table meet the hot gas which entering into the mill through wind ring, the materials will also rise. Then the materials enter into the separator through the mill’s middle shell, during this process, the materials and the hot gas have sufficient heat exchange with each other, and the water is quickly evaporated. The powder separator controls the size of the finished products, particles that are larger than the specified size will be separated and fall back into the grinding table, and particles that meet the fineness requirement will enter into the finished products warehouse through the powder separator.

| Items | 600,000t/a Slag rinding plant energy consumption | 450,000t/a Slag grinding plant energy consumption | 300,000t/a Slag grinding plant energy consumption |

|---|---|---|---|

| Output(t/h) | 105 | 65 | 50 |

| Annual output (×10,000 tons) | 60 | 45 | 30 |

| Total Power(KW) | 5400 | 3770 | 2860 |

| The power at 10KV(KW) | 4400 | 3140 | 2230 |

| Transformer specifications | 1000KVA | 630KVA | 630KVA |

| Power consumption /unit product (Kwh/ton) | 40 | 40~41 | 42 |

| Coal consumption /unit product (kg/ton) | 18 | 18 | 18 |

CHAENG steel slag vertical mill used in Xuzhou Steel’s steel slag grinding plant with annual output of 300,000 tons

In 2010, Xuzhou Steel and CHAENG cooperated to build a steel slag grinding plant with the production capacity of 45 tons per hour. The plant uses an advanced vertical roller mill to grind the steel slag. The product steel slag powder is mixed into cement or concrete as a mixture, to significantly improve its strength, impermeability and frost resistance. The steel slag powder produced by the plant is sold well in cement plants and concrete mixing stations around Xuzhou, and will be widely used in key projects in the province.

1. One set of system is enough, low operating costs. When the specific surface area of the products reaches 4500cm²/g, the average grinding capacity of the CHAENG’s steel slag vertical mill can reach 90t/h. But choosing ball mill, there are at least six sets of ball mill systems being required.

2. The power consumption of vertical mill system is 20% lower than ball mill. For many cement enterprises, the high energy consumption of ball mill system is such a big headache. But the new type of vertical mill is a kind of energy-saving and environment-friendly grinding equipment. Compared with ball mill system, vertical mill can save 30%-50% power. Also compared with traditional vertical mill, CHAENG’s steel slag vertical mill has large external circulation ratio, which can reduce the system power consumption by about 20%.

| System Solutions | ball mill | roller press + ball mill | vertical roller mill |

|---|---|---|---|

| System Power Consumption, kWh/t | 90 | 60 | 45 |

| Adaptability | bad (drying separately) | general (drying with V-Separator) | very good (drying inside the mill) |

| Total Power(KW) | bad | good | very good |

| Main reason of affecting operation rate | need to pour out the steel balls and clear the iron slag | need to repair the worn roller surface | need to repair the worn press roller and liner |

| Scale | difficult | easy | easy |

| Application and practice | 100,000 tons | 300,000 tons | / |

3. Low dust pollution

The ball mill requires several auxiliary equipment and conveyors due to the complicated system process, which will cause serious dust pollution. The steel slag vertical mill system is fully enclosed integrating functions of conveying, grinding, drying and powder separating and CHAENG also installs dust collectors in the vibrating screen frame and the feeding frame, which really achieves the “low” emission of dust.

4. High iron separation rate, improving economic efficiency

Steel slag generally has an iron content ranging from 1% to 3%. CHAENG optimizes the iron separation process of the vertical mill grinding system, and adds several iron removers to the feeding system, which greatly increases the iron removal amount and improves the integrated economic and environmental benefits.

5. Advanced slag discharge belt, to reduce the wear of grinding roller

The slag discharge belt adopts the advanced flat belt and paving device, which enables the iron remover suspended on the belt to more effectively magnetically select the iron-containing material discharged from the mill to prevent it from being re-grinding, so as to reduce the wear of the grinding roller.

6. Finished fineness can be guaranteed at 480-500m2/kg

CHAENG steel slag vertical mill uses many external circulation and effectively removes iron in the external circulation, which can make the iron content in the tailings less than 2%. And the steel slag powder has high fineness that the finished specific surface area can reach 450~500 m2/kg or above, and has good activity, which is suitable as cement active mixture and concrete admixture.