Application: gravel quarry, mining, quart,concrete mixing plants, dry mortar

Capacity: 30-800 t/h

Feeding size: 300-800mm

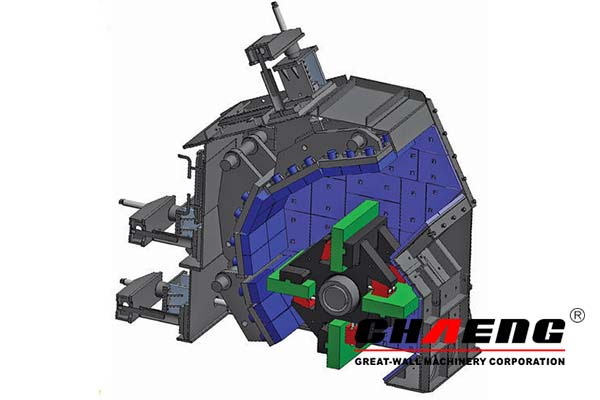

The impact crusher is a crushing machine that uses impact energy to break up materials. When the impact crusher is working, the rotor rotates at a high speed under the driving of the motor. When the material enters the action area of the flat hammers, it is broken through the collision with the hammers on the rotor, and then is thrown to the impact device for breaking again, and then rebounds from the impact plat to the hammer action zone. The process is repeated, the material enters the first, second and third impact chambers in order from large size to small size until the material is crushed to the required particle size and discharged from the outlet port.

| Model | Inlet port (mm) | Max. feed size (mm) | Capacity (t/h) | Motor power (kw) |

|---|---|---|---|---|

| PF-1007 | 400×730 | 300 | 30-70 | 45 |

| PF-1010 | 400×1080 | 350 | 50-90 | 55 |

| PF-1210 | 400×1080 | 350 | 70-130 | 110 |

| PF-1214 | 400×1430 | 350 | 100-180 | 132 |

| PF-1315 | 860×1520 | 500 | 130-250 | 220 |

| PF-1520 | 830×2040 | 700 | 300-550 | 440 |

1. Large feeding port and high crushing cavity, suitable to crushing the material with high hardness and big grain size, and less powder.

2. The gap between impact plate and hammer plate is adjustable, so the discharging grain size can be effective control and the grain shape is well.

3. The hammer, impact plate and lining plate are made of new type abrasion-proof material with long working life and impact protection, wear protection.

4. Because of the function of three-stage crushing and plastic, so the crushing ratio is high, and the product shape is cube and can optional crushing.

5. The multi-function hydraulic station has many function of hydraulic discharge gap with high speed, impact plate stable vibration and the body open automatically.

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel, Voestalpine and ASGT.