Equipment: GRMS Slag Vertical Mill

Grinding Material: Slag, Waster Slag, GBFS

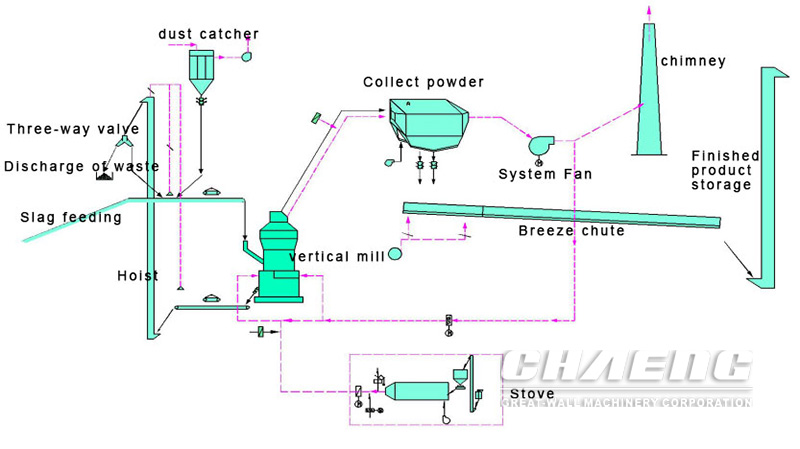

Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse

The ground granulated blast-furnace slag is an iron-making by-product. It is made by water quenching the molten slag flowing out of iron making blast furnace. Blast furnace slag, as a by-product of the steelmaking industry, is cheap. Whether it is used as an intermediate product and clinker to produce slag cement, or sold as a product for concrete making, its market prospect is very broad. Slag can be used as a mixture to produce ordinary portland cement and slag portland cement. The research shows that ground-granulated blast-furnace slag powder can significantly change the properties of cement and concrete.

So far, CHAENG has established successfully more than 130 slag production lines in the world.

Piles of slag are taken and fed by the forklift truck, and conveyed by a belt conveyor. During the process of conveying, slag raw material will be iron-removing and screening through magnetic separator and vibrating screen, and then go to the weigher cabin, elevator and last to the vertical roller mill for grinding process. The ground granulated slag powder is drying by the hot air supplied by hot blast furnace, and with the help of hot air, the powder selecting is made in the separator. The qualified slag powder particles will be collected by bag dust collector, then conveyed to and stored in the silos by the air slide and elevator.

Suggestions for the equipment selection

CHAENG already has more than 100 customers currently, and almost 80% of them built slag grinding plant with annual capacity of 1,000,000 tons, 600,000 tons, 300,000 tons. Below table has shown the three main equipment in aspects of model selection, energy consumption and so on.

| Product Specificationsct | GRMS 53.41 | GRMS 46.41 | GRMS 33.31 |

|---|---|---|---|

| Annual production (tons) | 1,000,000 | 600,000 | 300,000 |

| Designed production (t/h) | 150 | 90 | 45 |

| Raw materials input amount (t/h) | 188 | 125 | 65 |

| Actual output (t/h) | 160 | 105 | 55 |

| Final products fineness (m²/Kg) | 500 | 500 | 500 |

| Power consumption (KWh/t) | 26.5 | 28.5 | 30 |

| System power consumption (KWh/t) | 35 | 37 | 42 |

| Coal consumption (equivaient to standard coal) (kg) | 17 | 18 | 18 |

| Metal recovery of per ton slag (%) | 0.2-0.3 | 0.2-0.3 | 0.2-0.3 |

1. Starting from customer needs to avoid project investment waste caused by design

Optimize the overall layout of the production line according to specific conditions, so that the process is simple, smooth, compact, reasonable and beautiful, so as to reduce the floor space and reduce the consumption of pipes, cables, etc.

2. Energy saving and environmental protection

The whole production line adopts pulse bag filter for dust removal;

The production system adopts the negative pressure process, and the emission concentration of smoke and dust is ≤10mg/m³, which is lower than the national standard;

The vertical grinding process is more energy efficient than other grinding processes.

3. Project quality is guaranteed and delivery is fast

With a large steel casting base, the castings are made by the company from casting to finished products, and the quality and the construction period are guaranteed;

Have a professional project management team with strong coordination ability;

A professional installation team and the installation speed is fast;

An experienced debugging team and the debugging time is short.

4. Provide a full range of technical services to ensure worry-free system operation

During the project implementation process, the customer's technical personnel can participate in the whole process of the project;

Provide various operating procedures required by the project, online operation training, and cultivate a group of excellent technical talents for the customer's project operation.

According to customer needs, provide project operation services, efficiently manage, save costs, and increase the return on the capital operation.

1. In November, 2015, chairman of Indonesia Growth Steel Group came to CHAENG and signed the EPC Turkey Project contract of 300,000 t/y nickel slag grinding plant.

2. In May 2016, the vertical mill, auxiliary machine, and accessories of 300,000 t/y nickel slag grinding plant ordered by Indonesia Growth Steel Group were sent to Indonesia;

3. In September 2016, the project design, civil construction and equipment manufacturing of 300,000 t/y nickel slag grinding plant for Indonesian Growth Steel Group has been successfully completed, equipment installation and commissioning work were also near the end.

4. On November 3, 2016, 300,000 t/y nickel slag grinding plant EPC project of Indonesia was completed and put into production!