Weight: > 1 Ton

Material: Steel ZG45, ZG42CrMo, etc

Girth gear is an important transmission part of rotary kiln and ball mill equipment. The motor drives the pinion and the pinion drives the girth gear mounted on the cylinder shell, because of this, the ball mill starts driving. The girth gear is connected to the kiln shell by the bolt.

CHAENG can produce all kinds of large gear rings according to the drawings and sizes provided by customers.

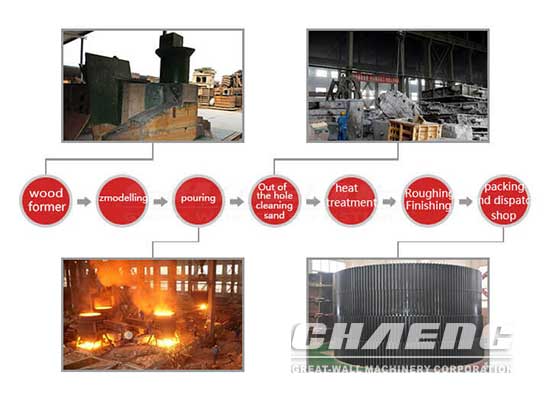

According to the customer’s requirement, CHAENG chooses the appropriate wooden model for design and makes the CAE casting simulation before casting. The casting is strictly in accordance with the process of “wooden model—sand molding—metallurgical casting—heat preservation—cleaning—heat treatment—rough finishing &fine finishing—package &delivery”, for the high-quality gear castings.

1.High abrasion resistance

The CHAENG adopts unique heat treatment technology in casting, which optimizes the gear’s structure, improves its hardness, and greatly enhances its wear resistance and the impact force.

2. High strength steel ensures, long working time

The CHAENG uses the high-strength steel for gear casting, and optimize it according to the transmission characteristics of rotary kiln, ball mill which ensure its stability during long-time working and prolong the service life of the components.

3. Efficient mass production, shorten the delivery time

CHAENG has strong strength for steel casting parts, and can produce in large quantities with short production time and high output.

In recent years, with the excellent quality, the girth gear made by CHAENG has been sold in Henan, Guangdong, Hubei, Jiangsu, Zhejiang and other provinces, and successfully exported Italy in 2012.

The girth gear exported to Italy by CHAENG

The girth gear manufactured by CHAENG has been applied to rotary kiln and ball mill in many cement plants, which provides reliable guarantee for the normal operation of rotary kiln and ball mill.

CHAENG girth gear used on rotary kiln in cement production line

1. It has its own large casting foundry, which is very few in the same industry

CHAENG has its own large casting base, and employs the top talents of casting technology to serve as the senior manager and its technical team. Now, CHAENG casting base already has the comprehensive ability to provide users a series services from semi-finished products casting to finished products and a complete solution to the key assembly parts.

2. GB Level 2 inspection standard to ensure the spare parts are qualified

The particular process solution can be made according to the different needs of customers. and each casting section will be strictly controlled. To make sure every product is 360 ° Nondestructive Flaw Test before delivery and no defective products leave from the factory.

The advanced technology and meticulous casting process ensure the quality of the castings, thereby makes the first maintenance time of the main spare parts 2-3 months later than that of the others.