Application: Cement, chemical industry, metallurgy, building materials and other fields;

Applicable materials: various ores, slag, coal mud, desulfurized gypsum, etc.

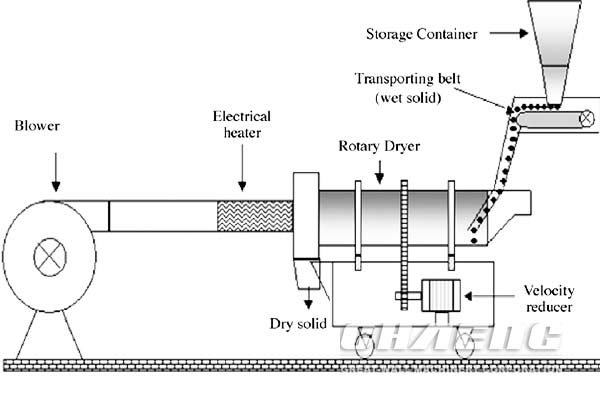

The dryer is mainly used for drying materials of certain humidity or particle size such as slag, coal mud and de-sulfurized gypsum. CHAENG, with its powerful technical advantages and service capabilities, is committed to providing customers with a complete set of energy-saving drying solutions.

Application: the dryer is mainly used for the drying materials of certain humidity or granularity in the fields of beneficiation, building materials, metallurgy and chemical industry. The dryer is widely used in chicken manure, slag, sawdust, coal mud, desulfurized gypsum, compound fertilizer, charcoal machinery, wood chip granule fuel, sawdust pressure block, agriculture & animal husbandry engineering and other industries.

Applicable materials: various ores, slag, coal mud, desulfurized gypsum, etc.

The fourth generation of the dryer developed by CHAENG adopts high &low temperature drying patent technology, which fundamentally solves the disadvantage of the former dryer. It has the advantages of intelligent fire-proof, reliable fire handling equipment, no any resistance in material discharging channel, multi-channel material discharging, uniform discharging, low crushing rate, and stable drying quality, and has been applied on all kinds of cement plant and chemical plant.

| Specification (m) | Cylinder Volume (m³) | Capacity (t/h) | Installation pitch (%) | Max inlet Temperature (℃) | Main Motor (kw) | Total Weight (t) |

|---|---|---|---|---|---|---|

| Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

| Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

| Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

| Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

| Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

| Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

| Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

| Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

| Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

| Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |

The dryer of CHAENG has been successfully applied in intelligent semi-coke drying project of Inner Monggol Bai Yanhu Chemical Co., LTD.

The project is completed on November 16, 2013, and tested successfully one-time. Original moisture of semi-coke is 20%, final moisture after drying is 1%, crushing rate is 2%, and capacity > 15 tons/h. All the indicators meet the design requirements completely.

The smooth production of the drying project is highly recognized by leaders and technical personnel of Bai Yanhu Chemical Co., LTD, who are very satisfied with its operability and practicability during the operation time.

1. The moisture is controllable;

2. Multi-channel intelligent anti-ignition;

3. Reliable fire handling equipment;

4. Coal & power saving, various heat sources can be used

5. Full automatic control;

6. Pollution-free emission;

7. Complete set of drying solution for granular material can be provided according to customer’s requirements.