27 Jul,2017 UTC+8 Views:

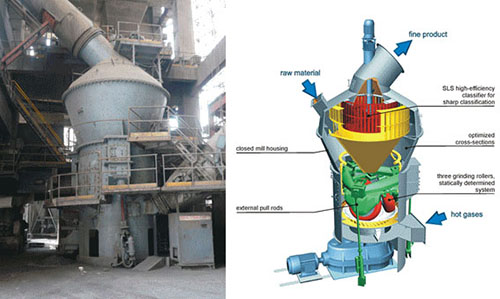

The vertical coal mill produced by our company is air-swept type, widely used in the grinding of raw cement, slag, cement clinker, raw coal and other raw materials. It gathers grinding, drying and powder selecting as a whole, with high grinding efficiency and high drying capacity ( the maximum material moisture can be up to 20% ). The vertical mill adopts dynamic powder selecting device, which comes with high powder-selecting efficiency and convenient adjustment of fineness.

After crushed by hammer crusher, the large materials become small ones and are sent to storage hopper by elevator, and then evenly sent to the upper distribution plate of the turn plate by vibrating feeder and sloping feeding pipe.The grinding disc is driving by motor through reducer. The material falls to grinding disc from the feed opening. The materials are driven to the edge of disc by the centrifugal force and crushed into fine powders by rollers. Then, the hot air from the nozzle take the fine powder to high effiency classsifer.The qualified powder are taken by the air to the powder collector to be collected, while the unqualified powder are sent back for regrinding.

Vertical Coal Mill Feature and advantages:

1. High grinding efficiency.

2. Low investment cost.

3. Low operation cost.

4. High drying ability.

5. Simple and stable operation.

6. Reliable product quality.

7. Easy Maintenance.

8. Environmental protection, low noises and dust.

Pre: Outstanding advantage of CHAENG cement production line

Next: how many Measures of Energy Saving and Emission Reduction in Cement Plant?