We have strong engineering design ability and perfect project management ability, and basing on it, we integrate supply chain resources vigorously. We can undertake production lines of different capacities from the new factory design to the production management. We can not only provide EPC turnkey projects, but also provide customized engineering design, civil construction, engineering installation, equipment R & D and manufacturing, personnel training, production commissioning, spare parts service, production management according to owners’ requirements.

The company has passed the three major certifications of quality, environment and health. With more than 500 sets of high-precision equipment and a large casting base with an annual output of 50,000 tons, we independently develop different types of machines covering crushing, screening, washing and conveying, which can meet the production requirements of stone with different characteristics.

With more than 60-year experience, Xinxiang Great Wall strives to explore new business development models and expand new business areas basing on its existing main business. The new business includes active lime production line and other products related to the building materials industry. We help our clients and partners have good development by extending the industrial chain.

1958-1970

In 1958, Liangcun Iron Wood Industry Association (predecessor of Xinxiang Great Wall) was founded.

In 1960-1970, Liangcun Iron Wood Industry Association renamed as Liangcun Agricultural Machinery Factory, which manufactured small agriculture machinery, later renamed as Liangcun Machinery Factory.

1971-1997

In 1971, the first φ1 ball mil was manufactured, which marked company formally enter into building material equipment industry.

In 1985, φ1.83m×6.4m ball mill won the Third Prize of Science and Technology Progress in Henan province

In 1988, Liangcun Machinery Factory renamed as Xinxiang Great Wall Mining Machinery Factory, and its tube mill of JINDU brand was chosen as provincial high-quality product by Henan People’s Government.

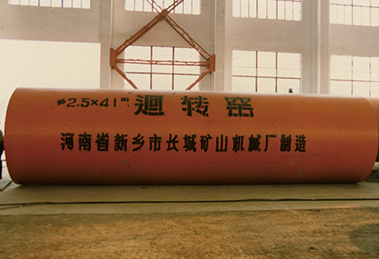

In 1993-1997, its self-designed and manufactured heavy equipment like large floor-type lathe, dual drive three-roller plate bender etc, started to produce all kinds of ball mill, rotary kiln. In the same year, the company was rated as national quality management standard enterprise, and the province’s top 20 enterprises.

1998-2010

In 1998, Jizhong Wang was appointed as the director of Xinxiang Great Wall Mining Machinery factory.

In 2001, the main equipment (three grinding mills and one rotary kiln) for the first 1000t/d new dry process cement production line was put into production in Meng Electricity Cement, which marked the company steps into new era of producing large cement equipment.

In 2002, it was renamed as Xinxiang Great Wall Mining Machinery Co., Ltd.

In 2005, the company was in charge of manufacturing main equipment ( the biggest φ4.6x13.5m drying centre discharging mill for raw material ball mill and φ4.2x13m cement ball mill) for two 3000 t/d new dry process cement production lines of Meng Electricity Cement, which was completed within 8 months, and become fastest in the delivery time in China.

In 2006, Xinxinag MeDa GaoPin Co., Ltd was founded, which is a well-known SMT company in Henan.

In 2007, our large steel casting base put into production, with the annual capacity 50,000 tons and the area of 330,000 square meters.

In 2008, 4.8x72m rotary kiln for 5000t/d new dry process cement production line was put into production in Chongqing. In the same year, the company successfully introduced GRM series vertical mill.

2011-2020

In 2011, the GRMR53.41 raw material vertical mill for 5000 t/d cement production line ,and GGBFS micro powder plant with capacity 600,000 t/y have been put into production successively.

In 2012, 1000,000t/y slag powder production line for Meng Electricity Cement has been put into production, several industrial waste slag powder grinding turnkey projects for Huangye have been put into production successively, which marked the company has achieved gorgeous turn from a single equipment supplier to grinding system integrated service provider.

In 2014, Xinxiang Zhongda Plastic Electricity Co., Ltd was founded, which is a well-known Henan plastic parts processing centre, who integrates with research & development, manufacturing and sales.

In 2015, 300,000 t/y nickel slag micro powder turnkey Project were put into production in Indonesia.

In 2016, energy saving rotary kiln & grinding mill successively exported to Vietnam, Kenya, South Africa, Pakistan, Indonesia, Uzbekistan, Korea, Turkey and many other countries and regions.

In 2017,the turnkey project undertook by our company for national industrial waste slag demonstration project –Ningbo Ziheng 1,500,000 t/y composite powder production line of Shanghai Baosteel was put into production.In September of the same year, it acquired Xinxiang Xiafeng Electrical Euipment Co., Ltd.

In 2018, several slag powder production lines with 1000,000t/y in Hainan, Hebei etc. were put into production, and many turnkey projects at home and abroad were installed and put into production. In the May of the same year, Xinxiang Yuntong Network Technology Co., Ltd was founded, which is a pilot enterprise of car-free carrier in Henan, and the first car-free carrier platform in Xinxiang city.Xinxiang Great Wall starts to step into new technology, asset-light industry.

With advanced equipment and excellent product quality, the company has won the recognition of customers at home and abroad and high praise from leaders, and achieved good cooperation with well-known enterprises in the world, such as CNBM, Shanghai Baosteel, Lafarge Cement etc.

Lei Qianzhi (the 1st on the left), President of China Cement Association, took a photo with Wang Jizhong, Chairman of CHAENG, in front of the New Dry Process Cement Production Line supplied by CHAENG in July 2004.

Jiang Minglin, Political Consultative Conference Member, Deputy Director of Ethnic and Religious Committee and Consultant of the State Council, wrote the inscription of "Flouring the Company by Science and Technology and Being the Pinionner" for CHAENG in 2005.

Kong Xiangzhong (the 6th on the right), Vice President of China Cement Association, and other leaders attended the 60th Anniversary Celebration of CHAENG in October 2018.