Feed size: 120-1500mm

Applications: gravel quarry, mining, coal mining, concrete mixing plants, dry mortar, desulfurization plant, quartz sand

Applicable materials: river gravel, granite, basalt, iron ore, limestone, quartz stone, coal gangue, construction waste

Jaw crusher is used in primary crushing for stones and bulk materials .It processes various kinds of ore with compression strength not more than 320mp. It has been widely applied in area of is widely used in mining, quarry, metallurgy, building, highway, railway, construction wastes processing, water conservancy and cement production, etc.

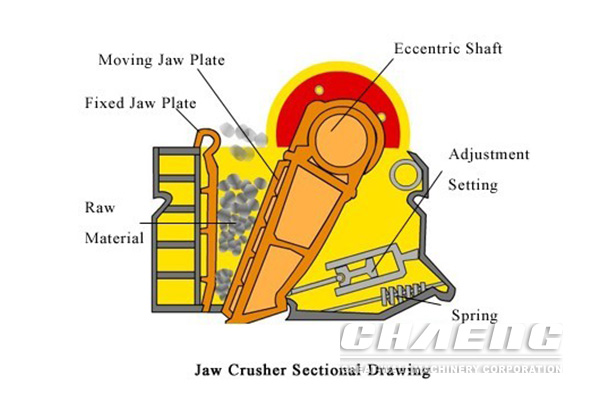

The belt and belt pulley are driven by a motor, and the movable jaw moves up and down via eccentric shaft. The angle between fixed jaw and movable jaw becomes smaller when the moving jaw runs down, then the materials are crushed into pieces. It becomes bigger when the movable jaw runs up. The movable jaw plate leaves the fixed jaw plate under the action of tension rod and spring , then the end products come out from the crushing cavity.

| Model | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kW) | Machine Size (mm) |

|---|---|---|---|---|---|

| GW200*350 | 200*350 | 170 | 2-6 | 6-7.5 | |

| GW250*400 | 250*400 | 210 | 5-20 | 6-15 | 1450*1315*1296 |

| GW250*750 | 250*750 | 210 | 8-22 | 6-30 | |

| GW500*750 | 500*750 | 425 | 45-100 | 6-55 | 1890*1916*1870 |

| GW600*900 | 600*900 | 500 | 70-120 | 6-75 | 2520*1840*2303 |

| GW750*1060 | 750*1060 | 630 | 130-260 | 8-90 | 2620*2302*3110 |

| GW900*1200 | 900*1200 | 750 | 220-380 | 8-130 | 3789*2826*3025 |

| GW1000*1200 | 1000*1200 | 850 | 230-380 | 8-130 | 3889*2826*3025 |

| GW1200*1500 | 1200*1500 | 1020 | 400-800 | 8-200 | 4930*3150*370 |

1.Big capacity and energy saving: no dead zone, feeding and crushing efficiency is greatly improved.

2.Good performance and good stability.

3.The jaw crusher is suitable for crushing ores or minerals whose compressive strength is below 300 Mpa.

4. Crushing cavity is deep and there is no dead area, which improves feeding capacity and output;

5. High reduction ratio and uniform final product size;

6. Spacing piece type discharge-hole adjustment device is reliable and convenient;

7. Reliable and safe lubrication system, convenient replacement of parts and small work load of maintenance;

8. Simple structure, operational reliability and low operation cost.

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.

Our long-term strategic partners: Arcelor Mittal, Tata Group, Pohang Iron and Steel Company, Germany CCE, Japan Chiba , Shanghai Baosteel,Voestalpine and ASGT.