Feed size: ≤1500mm

Applicable material: River gravel, granite, basalt, ironstone, limestone, quartz stone, diabase, construction waste, iron ore, gold

Application: Sand-stone quarry, mining, coal mining, concrete batching plant, dry powder mortar, power plant desulfurization, quartz sand

Crusher equipment as the main mining equipment, mainly for the different sizes of crushed stone, crusher equipment are jaw crusher, impact crusher, hammer crusher and cone crusher equipment. In order to meet the needs of breaking the high strength and high hardness micro carbon ferrochrome in metallurgy, mining, construction and other industrial sectors, CHAENG developed the multipurpose crushers.

Process introduction:

Crusher is generally used to deal with larger pieces of material, and product size is coarse, usually greater than 8 mm. Its structural feature is that there is a certain gap between the broken pieces, and they do not touch each other. Crusher can be divided into coarse crusher, middle crusher and fine crusher.

The working principle is as follows:

Characteristics

According to the crushing methods and mechanical structure characteristics (action principle), they are divided into six kinds in general:

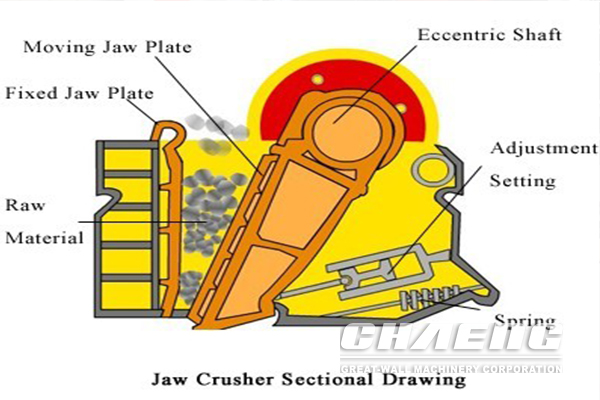

(1) Jaw crusher (tiger mouth). Its moving jaw plate periodically presses to fixed jaw plate to crush the ore sandwiched between them.

(2) Cone crusher. The ore block is between the two inner and outer cones, the outer cone is fixed, the inner cone is eccentrically swinging, and the ore block between them is crushed or broken.

(3) Roller crusher. The ore block is mainly subjected to continuous crushing in the slot between two opposite rotating round rollers. This kind of crusher also has grinding and stripping functions, and its toothed roll surface also has a splitting action.

(4) Impact crusher. The ore block is crushed by the impact of the rapidly rotating moving parts. This category can be divided into: hammer crusher; cage crusher; reaction crusher.

(5) Grinding mill. The ore is crushed by the impact and grinding functions of the grinding medium (steel ball, steel bar, gravel or ore block) in the rotating cylinder.

A. roller mill: grind material by rotating rollers.

B. Pan mill: use rotating disc with vertical or horizontal axis as a crushing part.

C. Centrifugal mill. Take use of centrifugal forces between high speed rotating parts and grinding medium to perform crushing action.

D. Vibrating mill. Take use of the high frequency vibration produced by rotating shafts, so that the grinding medium and materials strike against each other and crushing action is realized.

Various crushers have different specifications and different ranges of use. Jaw crusher or gyratory cone crusher is usually used for coarse crushing; standard cone crusher for medium crushing; and short head cone crusher for fine crushing.

| Model | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kW) | Machine Size (mm) |

|---|---|---|---|---|---|

| GW200*350 | 200*350 | 170 | 2-6 | 6-7.5 | |

| GW250*400 | 250*400 | 210 | 5-20 | 6-15 | 1450*1315*1296 |

| GW250*750 | 250*750 | 210 | 8-22 | 6-30 | |

| GW500*750 | 500*750 | 425 | 45-100 | 6-55 | 1890*1916*1870 |

| GW600*900 | 600*900 | 500 | 70-120 | 6-75 | 2520*1840*2303 |

| GW750*1060 | 750*1060 | 630 | 130-260 | 8-90 | 2620*2302*3110 |

| GW900*1200 | 900*1200 | 750 | 220-380 | 8-130 | 3789*2826*3025 |

| GW1000*1200 | 1000*1200 | 850 | 230-380 | 8-130 | 3889*2826*3025 |

| GW1200*1500 | 1200*1500 | 1020 | 400-800 | 8-200 | 4930*3150*370 |

The wide product range enables us to provide our customers with stand-alone machines or complete processing plants. Based on our customers’ request and budget, our experts make efficient, reliable solutions. Following customers’ order we produce strictly, what’s more, before placing the order every customer has the chance to visit CHAENG working machines or complete plant in the site.

To ease the trip for every visitor to China, in particular the first-time visitor, we provide FOR FREE all relevant visitor-friendly services including invitation letter preparation, hotel reservation, airport pick-up, incity transportation, and sightseeing guide, etc.

One-stop turnkey service

The CHAENG has 60 years’ experience in large-scale kiln and grinding equipment manufacturing, and it has provided customers at home and abroad with EPC construction for cement, mining and other projects, highly praised by all major enterprises.

Technical guidance allows customers to start operation fast

In order to supply better serve to customers, following the spirit of "maximum customer service", CHAENG will send engineers for commissioning, trial operation, hand-by-hand guidance on site after the purchase, and later CHAENG has professional customer service to perform regular tracking visit, so as to solve the equipment problems during operation!

"Three no-worry service”

CHAENG has many years of general contracting experience, and insists on the principle that everything is based on the interests of customers!

Let customers no worry in choosing, no worry during using and no worry when being serviced.