Capacity: 30-720 t/h

Power: 17-20 kWh/t

Finished fineness: 80 μmR 12-15%

Application: cement raw materials grinding in cement plant

Cement raw material includes limestone, gypsum, silica, clay, fly ash and other ingredients. In the process of cement production in a cement plant, the raw material needs to be ground through grinding equipment before being calcined.

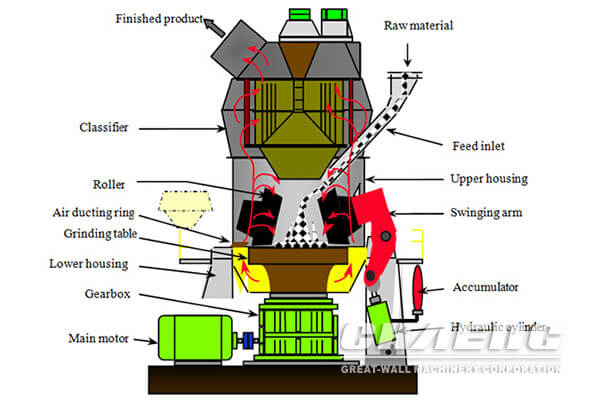

Vertical raw material mill is an important equipment widely used in the grinding section of cement raw meal (cement raw material) in the cement production process in cement plant. CHAENG manufactures cement raw material grinding mills with various specifications.

The GRMR Vertical Raw Mill of CHAENG is a kind of high efficiency, energy saving and environment friendly grinding equipment specially for cement raw material grinding system in cement plant. It has the advantages of high grinding efficiency, low power consumption, low noise, and little dust pollution, can meet the requirements of 300-10,000 TPD cement production line.

When it works, raw materials are fed in evenly by the feeder at the bottom of the hopper, then lifted to appropriate height by the bucket elevator, then sent into the mill through feeding pipe, the ground materials are brought into the powder classifier by the hot air generated by the hot air stove, at the same time, the materials are dried and classified, the unqualified materials fall down to be regrind, qualified fine powders are sent into powder collector, and then transported to the storage by the conveyor.

| Model | Grinding Table Diameter (mm) | Standard Ability Q (t/h) | Motor (kW) |

|---|---|---|---|

| GRMR22 | 2,200 | 65-75 | 710 |

| GRMR24 | 2,400 | 75-85 | 800 |

| GRMR26 | 2,600 | 85-95 | 900 |

| GRMR28 | 2,800 | 100-110 | 1000 |

| GRMR30 | 3,000 | 110-120 | 1120 |

| GRMR33 | 3,300 | 140-150 | 1400 |

| GRMR36 | 3,600 | 180-190 | 1800 |

| GRMR38 | 3,800 | 200-210 | 2000 |

| GRMR40 | 4,000 | 230-250 | 2240 |

| GRMR43 | 4,300 | 260-280 | 2500 |

| GRMR46 | 4,600 | 330-350 | 3150 |

| GRMR48 | 4,800 | 350-370 | 3350 |

| GRMR50 | 5,000 | 370-400 | 3550 |

| GRMR53 | 5,300 | 440-470 | 4200 |

| GRMR56 | 5,600 | 470-500 | 4500 |

| GRMR60 | 6,000 | 550-600 | 5300 |

| GRMR65 | 6,500 | 670-720 | 6300 |

| GRMR70 | 7,000 | 850-900 | 8000 |

Note: mill spectral pattern benchmark

(1) Material medium friction (MFs)=0.9~1.0;

(2) Material moisture max 15%;

(3) Refined powder granularity 4200~4500 cm²/g;

(4) Refined powder moisture 0.5~1.0%;

(5) The concrete mill installed power and technology parameter will be adjusted appropritely basing on the actual material property and requirements of owner;

The raw vertical mill of CHAENG has stable operation, high output and convenient replacement of parts. It has been recognized and purchased by customers in South Asia, Africa and other markets:

1. A 5000t/d cement production line EPC turnkey project in South Africa adopts GRMR53.41 raw material vertical mill of CHAENG.

2. A 5000t/d cement production line in Henan, China adopts GRMR53.41 raw material vertical mill of CHAENG.

5000t/d cement production line of Henan Meng Electric Group adopts GRMR53.41 raw material vertical mill of CHAENG.

1. High grinding efficiency and low power consumption

The power consumption of raw material vertical mill system is 9.7Kwh/t lower than ball mill, that is to say: in one year, a 5000TPD cement plant can save energy in clinker grinding system: 9.7kWh/t * 5000t/d * 300d=14,550,000 kWh, that means the cement plant clinker grinding system can save 14,550,000 kWh electricity one year.

2. Remarkable energy-saving and environmental protection, convenient maintenance

The system is in the state of negative pressure, no dust runs out and environment is clean, meeting the national environmental protection requirements. With the roller turning device, you can easily turn grinding roller out of the grinding mill for overhaul.

3. Original spare parts to reduce maintenance worries

Grinding rollers, rocker arms and other spare parts in the whole system are manufactured by CHAENG originally, ensuring the quality and greatly reducing the customer's worries of no where to find the spare parts.

4. Low noise, little dust pollution

When the vertical mill is running, the vibration is small, so the noise is low; the grinding system is integrally sealed, there is no dust leakage, and the dust pollution is small.