Application: Power plants, cement plants, lime plants and other coal grinding enterprises

Capacity: 12-38 t/h

Motor Power: 280-1250 kW

Fineness: 80 μmR 3%

Coal ball mill is the main equipment for grinding pulverized coal. The raw material of coal powder is coal with various hardness, and it drying in the coal mill grinding process to obtain finished coal powder which can be efficiently burned. Coal ball mills are widely used in the cement industry and thermal power generation industry, and are also suitable for metallurgical industry, chemical industry, sugar industry and other fields. Coal ball mills are also commonly used in the making process of pulverized coal fuel in calcining kiln such as a lime kiln, and in the production of pulverized coal raw materials in activated carbon processing. Coal mill is a kind of coal grinding machine. It can be divided into low speed coal mill, medium speed coal mill and high speed coal mill. These three kinds of coal mills have their own good points, customers can choose each one suitable for production according to the actual demands.

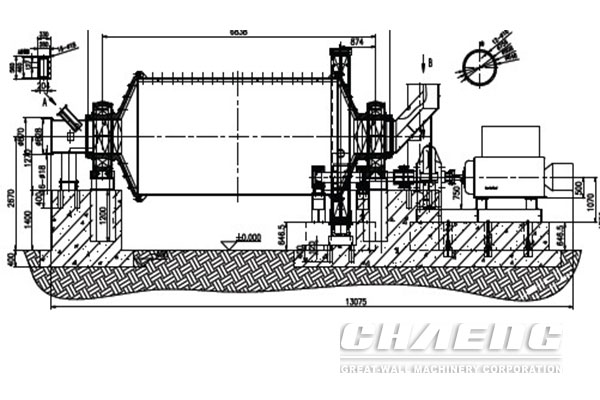

This energy saving steel ball coal mill is a rotating cylindrical drum with steel balls in the cylinder. When working, the steel balls in the cylinder continuously hit and squeeze the coal to grind the coal into pulverized coal.The materials enter the first cabin of the mill spirally and evenly through the feeding apparatus and hollow shaft. In the first cabin, there is stepped liner or corrugated liner, and steel balls with different specifications. The centrifugal force generating from the rotation of the cylinder brings steel balls to a certain height, and then the balls fall, thumping and grinding the materials. After coarse grinding in the first cabin, the materials enter the second cabin by single-wall partition. There is flat liner and steel balls in the second cabin, where the materials are grinded further. Finally, the powder is discharged through discharge grate and the grinding operation is finished.

| Model | Output(t/h) | Rotate Speed(r/min) | Feed size(mm) | Effective Volume(m³) | Grinding Media Load(t) | Drive mode | Motor(KW) | Main reducer | Weight(t) |

|---|---|---|---|---|---|---|---|---|---|

| Φ2.4×4.75 | 12 | 20.4 | ≤25 | 19.3 | 22 | Rim drive | 280 | ZD60 | 50 |

| Φ2.4×4.5+2.0 | 12 | 20.4 | ≤25 | 18.3 | 22.6 | Rim drive | 280 | JD450 | 70.1 |

| Φ2.6×5.25+2.25 | 13-15 | 18.7 | ≤25 | 25.8 | 34 | Rim drive | 400 | MBY560 | 80 |

| Φ2.8×5.75+2.25 | 18-20 | 18.7 | ≤25 | 32.9 | 38 | Rim drive | 500 | MBY630 | 118.5 |

| Φ2.9×4.1 | 16 | 18.8 | ≤25 | 27.1 | 35 | Rim drive | 500 | JDX560 | 74 |

| Φ3.0×6.5+2.5 | 20 | 18.4 | ≤25 | 43.3 | 46.5 | Rim drive | 630 | JDX630 | 119 |

| Φ3.2×6.5+2.5 | 28 | 18 | ≤25 | 67 | 65 | Rim drive | 710 | JDX800 MBY800 |

153 |

| Φ3.4×6.0+3.0 | 30 | 17.47 | ≤25 | 64 | 60 | Rim drive | 900 | JDX800 | 167 |

| Φ3.4×7.5+1.5 | 30-38 | 17.5 | ≤25 | 64.1 | 70 | Rim drive | 1000 | MBY800 | 178 |

| Φ3.6×6.5+2.5 | 32 | 17 | ≤25 | 69 | 60 | Rim drive | 1000 | MBY800 | 204 |

| Φ3.8×7.0+2.5 | 38 | 16.4 | ≤25 | 75 | 80 | Rim drive | 1250 | JDX800 | 216 |

1. High grinding efficiency

The grinding lining plate for the coal mill adopts combination design. Aiming at the different stages inside the coal mill, use different lining structure, which improves grinding efficiency greatly.

2. Custom on demand, flexible configuration

According to the different models, the coal mill can use edge transmission or central transmission, flexibly on configuration.

3. Output is 12~38t/h, finished fineness is up to 80μmR 3%

The output of the CHAENG coal mill is 12~38t/h, and the fineness of the finished product is up to 80 mR 3%. It achieves the goal of high yield and high fineness, and provides an efficient and energy-saving grinding equipment for the production of high quality pulverized coal.

1.Lafarge Group purchased from CHAENG coal mill used in 1000t/d cement production line. The coal mill works very well.

2. Pakistan 1000t/d cement plant purchased coal mill from CHAENG.

3. Φ3.2×13m three-bin high fine ball mill and coal mill are used in 1200t/d cement clinker production line in Xinjiang, China, and play extremely good production performance.