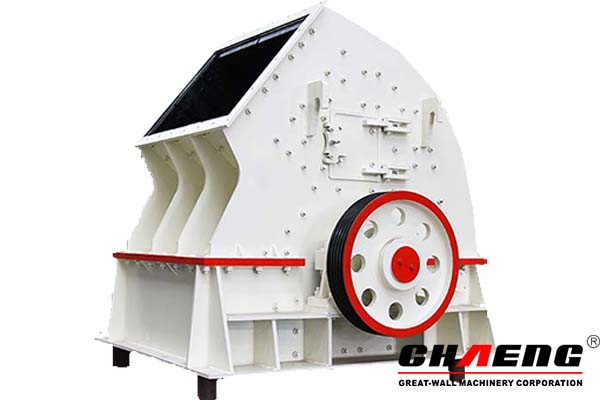

Application: gravel quarry, mining, coal mining, concrete mixing plants, dry mortar, desulfurization plant, quart

Capacity: 5-150 t/h

Feeding size: ≤600–≤1200 mm

In the hammer crusher, the motor drives the rotor to rotate at a high speed through the belt, and on the rotor there are series of hammers. When the materials get into the working area of hammers, the rotating hammers with high rotation speed are crushing them; the crushed materials meeting the required size can be discharged by the outlet and become the final products; the bigger particles are brought back to the crushing area by the hammers for being re-crushed until they reach the required size

| Model | Rotor (Diameter × Length) | Inlet port (Width × Length) | Feed size (mm) | Minimum production capacity (T/h) | Maximum production capacity (T/h) | Installed power (Kw) | Outline L (mm) | Outline W (mm) | Outline H (mm) |

|---|---|---|---|---|---|---|---|---|---|

| GCPF1308 | 1310×790 | 850×800 | ≦600 | 100 | 160 | 132 | 2818 | 2100 | 2390 |

| GCPF1510 | 1500×950 | 1000×900 | ≦700 | 160 | 210 | 264 | 3260 | 2414 | 2750 |

| GCPF1512 | 1500×1160 | 1200×900 | ≦750 | 250 | 320 | 320 | 3260 | 2624 | 2750 |

| GCPF1615 | 1650×1452 | 1500×1200 | ≦1000 | 420 | 500 | 400 | 3456 | 2915 | 3185 |

| GCPF1815 | 1776×1510 | 1575×1300 | ≦1000 | 600 | 800 | 500 | 3822 | 2912 | 3436 |

| GCPF1620 | 1660×1900 | 2000×1200 | ≦1200 | 800 | 1000 | 800 | 3500 | 3100 | 3200 |

1. Large crushing ratio and large feeding amount.

2. Low operating cost, low production cost, and the remarkable power saving effect compared with the conventional three-stage breaking.

3. Adopt professional wear-resistant hammer with long service life, maintenance cost is low.

4. Simple structure and lightweight, easy operation and maintenance.

5. Single molding without secondary crushing.

Founded in 1958 and located in Xinxiang, Henan province, CHAENG with 60-year experience in equipment manufacturing covers an area of 330,000 m2 and its annual production value is 1 billion yuan. The company specializes in manufacturing tube mills, rotary kilns, vertical mills and large steel casting and can undertake the EPC projects of cement production lines, active lime production lines, blast furnace slag/ steel slag/ nickel slag grinding plants, and its products are sold to more than 50 countries and regions in Southeast Asia, Central Asia, South Asia, North America, South America and Europe.