Materials: Nickel Slag

Main Equipment: GRMSS Slag Vertical Mill

Matching Equipment: belt feeder + vibrating screen + slag vertical mill + hot stove + dust collector + finished product warehouse

Piles of slag are taken and fed by the forklift truck and conveyed by a belt conveyor. During the process of conveying, nickel slag raw material will be iron-removing and screening through magnetic separator and vibrating screen, and then go to the weigher cabin, elevator and last to the vertical roller mill for grinding process. The ground nickel slag powder is dried by the hot air supplied by the hot blast furnace, and with the help of hot air, the powder selection is made in the separator. The qualified nickel slag powder particles will be collected by bag dust collector, then conveyed to and stored in the silos by the air slide and elevator.

Performance comparison of cement clinker before and after adding nickel slag

| Clinker | C₃S % |

f-CaO % |

Stability Pass Rate % |

Coagulation Time min |

degree of bending resistance MPa |

Compressive Strength MPa |

|||

| Initial Solidification | Final Solidification | 3d | 28d | 3d | 28d | ||||

| No nickel slag added | 54.68 | 2.16 | 83.5 | 100 | 151 | 5.8 | 8.7 | 31.2 | 54.3 |

| nickel slag added | 57.13 | 1.73 | 98.4 | 117 | 166 | 6.3 | 9.1 | 34.7 | 58.9 |

1. Lake blue is the main color, expressing new ideas of harmony between manufactured products and natural ecology

In the system design of the upgraded version 2.0, lake blue is used as the main color, supplemented by the corresponding light blue and white. The three colors run through the production line, enthusiastically expressing the good wishes of the Xinxiang Great Wall to live in harmony with the natural ecology.

2. 2.0 New application of technology, adding value to customers in subtleties

CHAENG has also carried out dust reduction treatment for the entire system. From the stacking to the finished product, a fully enclosed production is adopted. On the one hand, it can eliminate most of the dust and achieve the purpose of environmental protection and dust collection. On the other hand, it also adds value to the new system services.

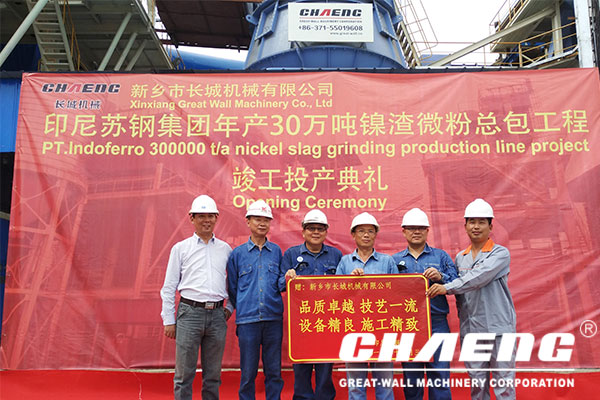

Nickel Slag Grinding Plant in Indonesia

After the operation evaluation, the output of the project is 50 tons per hour, the specific surface area is 450㎡/kg, and both the output and quality meet the design requirements. Indonesia Suzhou Steel Group is very satisfied with the service of CHAENG.