Capacity: 21-155 t/h

Motor Power: 800-3550 kw

Specific surface area: 330-380m²/kg

Application: Cement plant, grinding plant, etc.

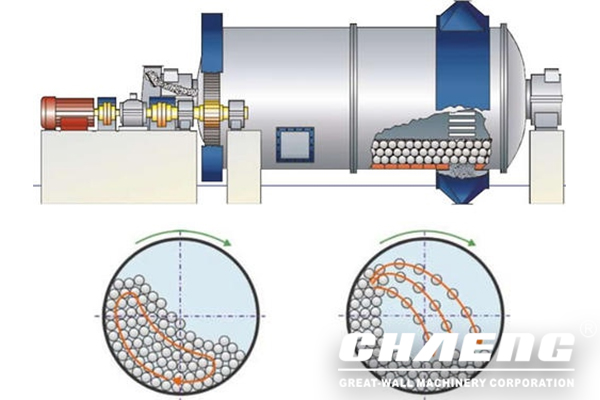

Cement ball mill is mainly used in the grinding of finished products and raw materials in cement plants. They are also suitable for metallurgical, chemical, and electric power companies to grind various ores and other grindable materials.The high-efficiency and energy-saving ball mills produced by CHANEG are based on traditional ball mills. This modified new equipment can reduce energy consumption by 30% and increase processing capacity by 15%-20%. According to different requirements, the cement ball mill can adopt edge drive or center drive, and the configuration is flexible.

The material enters the first chamber of the ball mill spirally and evenly through the hollow shaft from the feeding device. There is a step liner or a corrugated liner inside the chamber, which contains steel balls of different specifications. The rotation of the cylinder generates centrifugal force to bring the steel balls to a certain height and then fall. It has a heavy blow and grinding effect on the material. After the material reaches the rough grinding in the first bin, it enters the second bin through the single-layer partition board, which is lined with a liner and steel balls inside to further grind the material. The powder is discharged through the unloading grate to complete the grinding operation.

| Model | Output(t/h) | Rotate Speed(r/min) | Feed size(mm) | Grinding Media Load(t) | Effective Volume(m³) | Drive mode | Motor(KW) | Main reducer | Weight(t) |

|---|---|---|---|---|---|---|---|---|---|

| φ2.4*13 | 21-23 | 20.3 | ≤25 | 65 | 51.7 | Rim drive | 800 | JDX710 | 116 |

| φ2.6*13 | 28-32 | 19.61 | ≤25 | 75 | 60 | Rim drive | 1000 | JDX800 | 149 |

| φ3.0*13 | 33-37 | 18.08 | ≤25 | 108 | 80.9 | Rim drive | 1400 | JDX900 | 172.3 |

| φ3.2*13 | 45-50 | 18.04 | ≤25 | 128 | 92.4 | Rim drive | 1600 | MBY1000 JDX1000 |

218 |

| φ3.2*14 | 48-52 | 18.04 | ≤25 | 138 | 99.8 | Rim drive | 1800 | MBY1000 | 228 |

| φ3.4*11 | 45-50 | 18 | ≤25 | 115 | 94 | Rim drive | 1600 | MBY1000 | 205 |

| φ3.5*13 | 55-60 | 17.09 | ≤25 | 160 | 111.2 | Rim drive | 2000 | JDX1000 MBY1000 |

250 |

| φ3.8*12 (closed-circuit) | 110 | 16.6 | ≤25 | 175 | 123.6 | Central drive | 2500 | JQS2500 | 203 (excluding drive parts) |

| φ3.8*13 | 66 | 16.4 | ≤25 | 195 | 129.3 | Central drive | 2500 | MFYX250 | 286 |

| φ4.0*13 | 80-85 | 15.5 | ≤25 | 235 | 155 | Central drive | 2800 | JS140-A | 220 (excluding drive parts) |

| φ4.2*13 (closed-circuit) | 140-155 | 15.6 | ≤25 | 240 | 157 | Central drive | 3550 | JS150-B/MFX355 | 287 (excluding drive parts) |

| φ4.6*13 (closed-circuit) | 170-180 | 15.7 | ≤25 | 292 | 210 | Central drive | 4500 | MFY450 | 346 (excluding drive parts) |

Since 1998, cement factories from more than 50 countries and markets worldwide have purchased more than 2000 ball mills from CHAENG. Therefore, CHAENG has been praised as the most cost-effective enterprise in China.

1. With high stability, won a number of new patents

Double-sliding-belt tube mill of CHAENG is the first one in China to solve the problem that grinding mills cannot continuously work due to the high temperature of sliding-belt shaft bush at the discharge end, and won national patent for utility models with patent No.: ZL201020285841.9. Many examples prove that CHAENG cement ball mill can run steadily for a long time.

2. Novel structure, strong production capacity

CHAENG cement mill adopts the latest and unique streamline design of the world, to reduce the ventilation resistance, increase the effective volume, make discharge easy, and improve the output of the mill. Lining plate in the mill adopts combined structure design, and different lining plate structures are used in different stages of raw material mill, so that the grinding efficiency is improved greatly. Its material drying capacity can reach 10%~15%.

3. Specific surface area of finished product is 3300-3800cm²/g

Specific surface area of the cement produced by CHAENG cement mill is 3300-3800cm²/g. Compared with other mills in the same industry, CHAENG cement mill has advantages of high-fineness product, larger specific surface area,quick hydration reaction, and fast strength development.