CHAENG (Xinxiang Great Wall) signed a

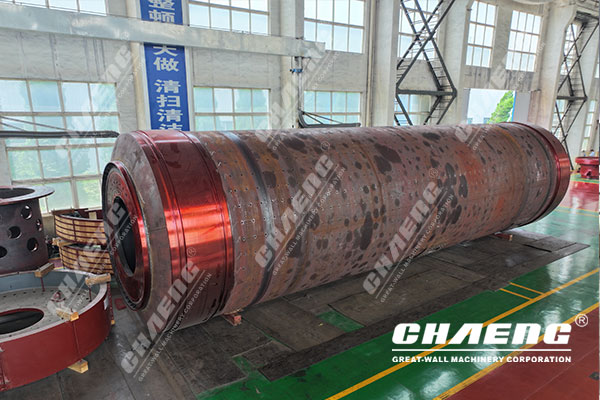

4.2*14.5 cement ball mill project with a cement plant in Xinjiang. As of so far, the entire production process of the ball mill cylinder has been completed.

After multiple processes such as raw, rolling, welding, etc., our ball -grinding barrel can use 6*6*18.5m cylinders to automatically control the overall annealing furnace for overall annealing. Performance, eliminating the stress of welded seams, and reducing the tendency of deformation and cracking in later use. It has greatly improved the performance of the ball mill, which can extend the life of the ball mill.

After the annealing, the cylindrical body is processed, drilling, assembly and other links, and a qualified ball mill cylinder is successfully completed.