16 Jan,2023 UTC+8 Views:

In order to maximize the utilization of resources, after ultrafine grinding of various industrial waste residues in the metallurgical industry, thermal power industry, and coal industry, make ultrafine powder replaces part of cement and concrete aggregates to produce high-performance and ultra-high-performance concrete. It is an inevitable choice for the transformation and upgrading of cement plants and even grinding stations.

Steel slag powder, fly ash and other low-activity materials are mixed in a certain proportion or mixed with some slag powder for ultra-fine grinding. The mill adopts an open-circuit system or a closed-circuit system. The specific surface area of the composite ultrafine powder is controlled at 650-700㎡/kg, and the sieve residue is generally controlled at 30μm sieve ≤ 1%. Deeply stimulate the activity of admixtures such as mineral powder and fly ash, and then achieve the expected indicators.

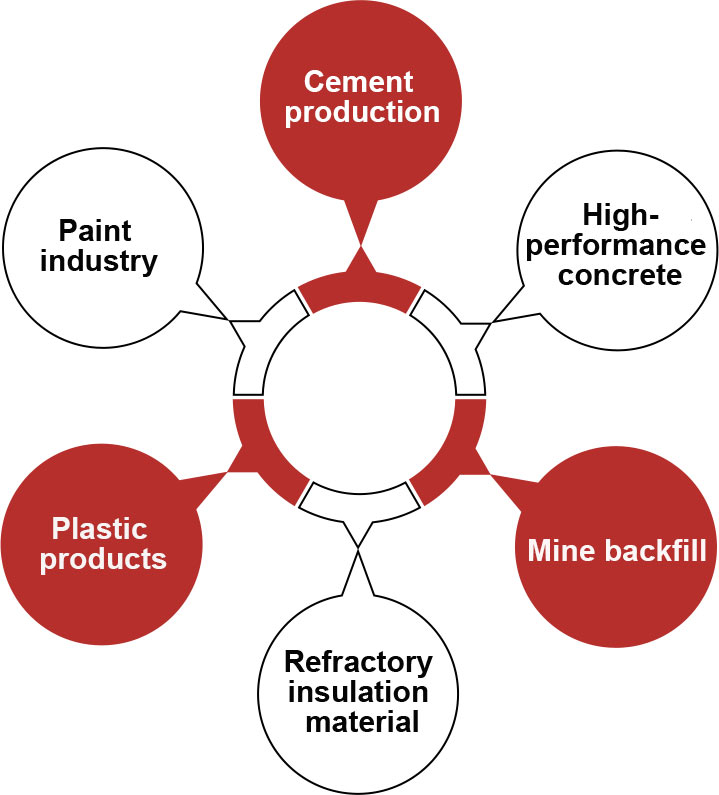

Application:

Applicable raw materials for CHAENG superfine grinding ball mill:

Recently, two sets of 3.5*17.5m ultra-fine ball mills ordered by the customers from Jiaozuo have been successfully delivered. After the equipment is put into production, it will successfully improve the fineness of finished products and reduce production costs!

Pre: Reuse of industrial waste slag

Next: CHAENG won the honorary title of "Excellent Private Enterprise in Xinxiang City"