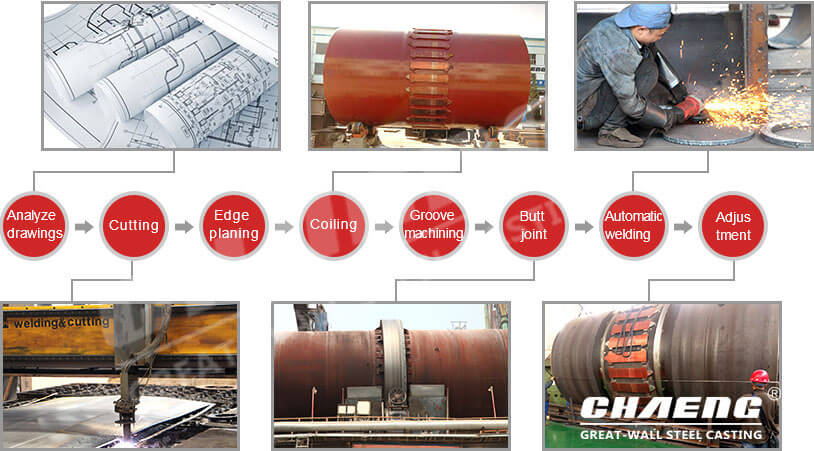

The rotary kiln shell is rolled from steel plates such as boilerplates and Q235C plates and requires highly on dimensional accuracy and geometric tolerances. Its processing quality directly affects the strength and tightness of the component.

According to the detailed requirements of the drawings, and adopting the local forming method, the specific manufacturing process and welding method of the single-section kiln shell are formulated. After the kiln shell section is assembled and welded, post-weld processing is required, including non-destructive testing, post-weld heat treatment, pressure-resistant experiments, and other technological processes to ensure the high quality of the rotary kiln shell.

CHAENG has close cooperation with many companies of various industries, supplying them with spare parts with good performance to improve the practical effect and extend the service life of the equipment. CHAENG has won the high praise of customers!

1. Cost-effective

CHAENG has advanced casting equipment, strictly follows the national lever-2 detection standards, and executes a 360° all-round nondestructive testing system, to ensure the reliable quality and long service life of steel castings. CHAENG is hailed as a "high cost-effective steel castings manufacturer".

2. Fast delivery

CHAENG has strong technical teams, detailed production scheduling, a wide range of raw materials purchase channels, and a perfect logistics delivery system, making efforts to achieve as fast delivery period as required.

3. “Three-heart” service

The 24h fast response and the customer services in all 365 days rest your heart when you make choice, ease your heart when you use the products, and satisfy your heart when you enjoy the services.